Mechanical Engineering

Mechanical Engineering

About the Department

| PROGRAMME | Intake |

| B.E Mechanical Engineering | 60 |

| M.E Thermal Engineering | 18 |

The Department of Mechanical Engineering at Excel Engineering College, Komarapalayam is established in the academic year of 2008-09 with a yearly intake of 60.The intake of the department has been increased to 120 per year from the year 2012 onwards. Also PG Course M.E Thermal Engineering is introduced in the academic year of 2014-15 with yearly intake of 24.

The Department is continuously striving to achieve excellence in Education, Academic and Industry Oriented Research as well as consultancy work with service to the society. We aim to provide our students with a perfect blend of intellectual and practical experiences that helps them to serve our society and address a variety of needs.

The Mechanical Engineering discipline involves the application of principles of physics for analysis, design, manufacturing and maintenance of Mechanical System. It requires a solid understanding of key concepts including Mechanics, Kinematics, Thermodynamics and Energy. Mechanical Engineers use these principles and involve themselves in design and analysis of Automobiles, Aircraft, Heating and Cooling systems, Water Craft, Manufacturing plants, Industrial Equipments and Machinery, Medical Devices and more.

HOD’s Message

Dr.M.Kathiresan Ph.D.,

Educational Qualification : PhD.,

Teaching Experience : 23 Years

Industry Experience : 3.5 Years

Greetings overflowing with warmth and heartiness from the Department of Mechanical Engineering at our college. Our institution has experienced remarkable growth, actively engaging in a myriad of activities that have unearthed the hidden talents of both our students and staff. Mechanical engineering, one of the oldest and most expansive engineering disciplines, plays a pivotal role in enhancing economic growth, enriching our lives, and elevating the overall quality of life worldwide. This professional core engineering field is responsible for the design, manufacturing, and maintenance of products across various industries. Within our department, we are proud to boast a team of dedicated, highly qualified, and experienced faculty, coupled with excellent infrastructure and laboratory facilities. We are continuously dedicated to enhancing the quality of education and maintaining our leadership position in the field of engineering and technology.

Our department’s core values not only foster the academic growth of our students but also nurture their overall personality development, making them competitive and globally adept. Our faculty members are actively engaged in furthering their knowledge, attending various training programs, publishing research papers and books, and pursuing patents. Many of them are actively involved in cutting-edge research. In our relentless pursuit of excellence, we organize seminars, conferences, and offer value-added courses to keep both faculty and students up-to-date with the latest developments in the field of technical education. Additionally, we have established partnerships with industries to provide internship opportunities during the course of study.

We take pride in the fact that numerous students from our department are pursuing higher education in leading universities within India and overseas. Moreover, our alumni have secured prestigious positions in multinational companies. We have every confidence that our students will become invaluable assets to any organization they choose to join.

Vision & Mission

List of Laboratory

Metrology & Measurements Lab

Engineering Practices Lab

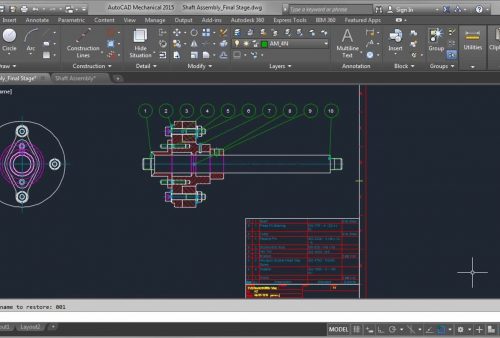

CNC Lab

Additional Labs for Advanced Learning

Hyundai professional center

Research Centre

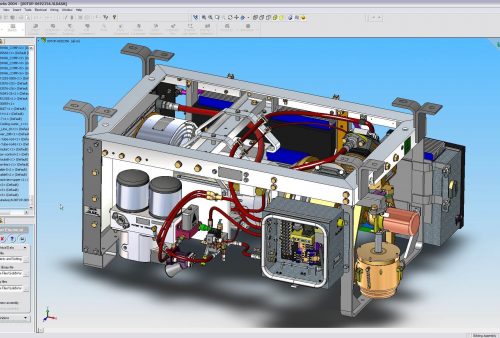

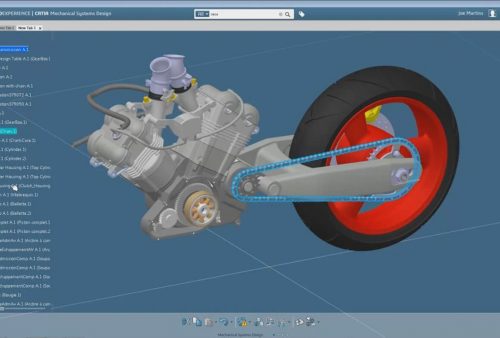

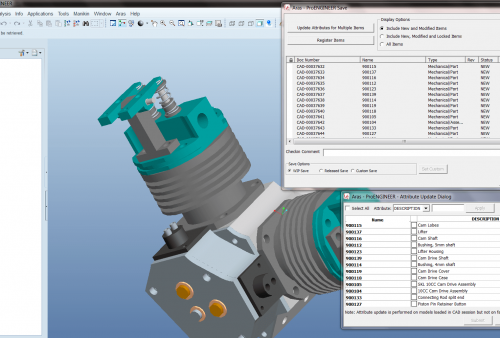

Dassault Systems Centre of Excellence

Programs Outcomes & Objective

Programme Outcomes (POs)

Program Outcome describe the knowledge, skills and attitudes the students should have at the end of a four year engineering program.

Engineering Graduates will be able to:

- Engineering Knowledge: Apply the knowledge of mathematics, science, engineering fundamentals and an engineering specialization to the solution of complex engineering problems.

- Problem Analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- Design / Development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

- Conduct investigations of complex problems: Use research-based knowledge and research methods, including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

- Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling of complex engineering activities with an understanding of the limitations.

- The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- Environment and Sustainability: Understand the impact of the professional engineering solutions to societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

- Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- Individual and team work: Function effectively as an individual and as a member or leader in diverse teams, and in multidisciplinary settings.

- Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- Project management and finance: Demonstrate knowledge and understanding of the engineering management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- Lifelong learning: Recognize the need for and have the preparation and ability to engage in independent and lifelong learning in the broadest context of technological change.

Programme Specific Outcomes (PSOs)

Program Specific Outcomes are statements that describe what the graduates of a specific engineering program should be able to do.

- Ability to apply their knowledge to design and analysis by using software tools.

- Engage them professionally in industries or as entrepreneurs in the field of manufacturing and design

Department Activities

Corona Virus Awareness Program

Our MACHINE WARRIOZ ASSOSIATION, Department of Mechanical Engineering has conducted a Corona virus awareness program. In this program nearly 400 students are participated and benifited. Chief guest of the program Dr.S.Vengadesh Senior Medical officer, Excel Homeopathy Medical College.

Summary Report on Alumni Guest Lecture

An alumni guest lecture was conducted by our machine warriors association on (25-01-2020).in that the chief guest lecture was given by Mr. Karthikeyan.

In that he shared many things about the industries and his knowledge gained during the industrial trainings and how to work and the oppourtunites avilable in industries

Finally, he concluded his speech by sharing his innovational thoughts and the and the gate ways available in the society for mechanical engineers based on career.

Summary Report on Guest Lecture on NDU

Our MACHINE WARRIOZ ASSOCIATION, Department of Mechanical Engineering has conducted a guest lecture on Non Destructive testing and Materials by Mr. Ramasamy Managing partner Dr.Abdhul Kalam, Educational Institutions, Salem. on (14-02-2020).

In this heat of our department Mr.G.Nallakumarasamy has given an introduction speech about the non destructive testing and then followed by that he welcomed the chief guest with honour.

Then our chief guest Mr.Ramasamy Managing partner Dr.Abdhul Kalam Educational Institutions,salem. has explained about the non destructive testing and briefly about the usage of an non destructive testing.

Then the function was concluded by giving an brief account on the non destructive testing and the knowledge about NDU which was very useful to our students of our department. Then the final address was given by our student.

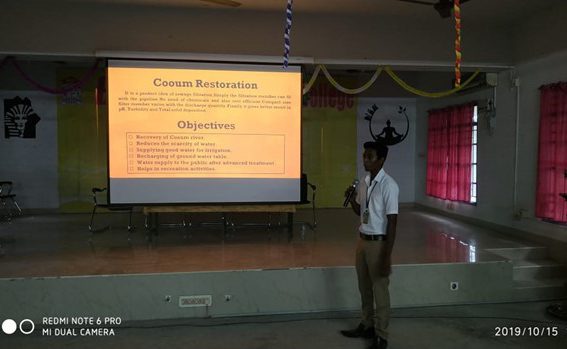

Report on Dr.A.P.J.Abdul Kalam Birthday Celebration

Machine warriorz association of mechanical engineering ‘MY IDEA’ competition conducted on (15-10-2019) at excel engineering college for celebrating Dr.A.P.J.ABDUL KALAM’S 88th birthday.

Entrepreneurship Development Centre (EDC)

On (23-01-2020) in our department of mechanical engineering an Guest Lecture from Entrepreneurship Development Centre (EDC) by our machine warriors association.

In that function introduction was given by our head of mechanical department Mr.G.Nallakumarasamy and head of aeronautical department Mr.K.Sankaran.Then followed by that our chief guest has given a brief account on the Entrepreneurship Development Centre (EDC).

Finally, the function was concluded up giving the brief account (EDC).and the benefits of (EDC) and the opportunities available in (EDC).

Report on Industrial Explorer’19-6th Edition

The function was started by enlightening the glorious lamp by our chief guests of the function.

Then the light lamp (kuthu vilaku) was lightened by our chief guest and students.

Mr MOHANDOSS KRISHNASWAMY plant head-HR, Hindustan motor finance corp. ltd. Thiruvallur. Honoured our Dr R.Nallusamy principle of engineering and technology.

Mr ARUNMOZHIARASU.K.K Sr.manager/quality EASi(an alleges group company), Bangalore honoured our placement director Dr.D.Devakumar IRRP.

Mr.GURUPRASAD director solutionbuggy, Bangalore honoured our Dr.S.P.Venkadesan HOD department of mechanical-S&H-E&T.

he shared his life time experience which was very useful to our student, in various ways the he shared his knowledge which he gained in his life time is various occasions. Then he made the student to know there level of knowledge his speech had made the students to lead a successful future.

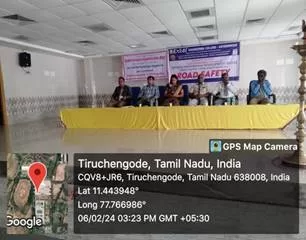

Road Safety

Date: 06.02.2024

Name of Coordinator: Dr.N.Venkatachalam Associate Professor/Mech

Mapping with POs,PSOs: PO – 6,7,8,9,12, PSO- 2

Number of Participants: 665 Students , 13 Staff Members

Description:

Rotaract Club of Excel Engineering College organized an awareness program on “Road Safety” to all the Rotaract members and third year student members in Mini Auditorium on 06.02.2024 10.00 am to 11.45 am, during the session Mrs.Pongulazhi RTO, Pallipalayam greeted the students for the promoted safety measures and to adhere with the driving license to achieve greater miles stones in the future. This program was coordinately organized by Dr.N.Venkatachalam, Coordinator, Rotaract club.

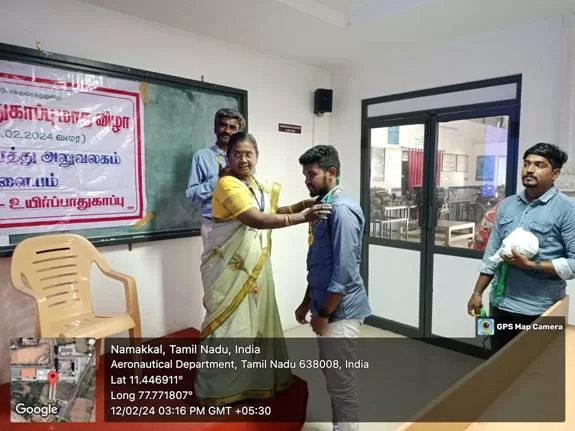

Awarding Ceremony for Rotaract Members

Date: 12.02.2024

Name of Coordinator: Dr.N.Venkatachalam Associate Professor/Mech

Mapping with POs,PSOs: PO – 6,7,8,9,12, PSO- 2

Number of Participants: 65 Students , 3 Staff Members

Description:

Rotaract Club of Excel Engineering College organized a program on “Awarding Ceremony for Rotaract Members” to all the Rotaract members in Hyundai Development seminar Hall on 12.02.2024 3.00 PM to 3.45 PM during the session Mrs.Pongulazhi RTO, Pallipalayam greeted the students for the promoted safety measures and to adhere with the driving license to achieve greater miles stones in the future. This program was coordinately organized by Dr.N.Venkatachalam, Coordinator, Rotaract club.

Design of Mechanical Systems for all Terrain Vehicle

Date: 02.02.2024

Name of Coordinator: R.Vinoth Professor/Mech

Mapping with POs,PSOs: PO – 6,7,8,9,12, PSO- 2

Number of Participants: 216 Students , 13 Staff Members

Description:

Department of Mechanical Engineering organised an academic guest lecture on “Design of Mechanical Systems for all Terrain Vehicles” to all the mechanical engineering stream students in Pavaiyammal Hall on 02.02.2024 from 10.00 AM to 11.45 AM, during the session Dr. A.Vadivel, Associate Professor, Mech, Sri Ramakrishna Engineering College, Coimbatore greeted the students for the promoted new technologies and to adhere with the Design of Mechanical Systems for all Terrain Vehicle to achieve greater miles stones in the future. This program was coordinately organized by all the mechanical department faculty members.

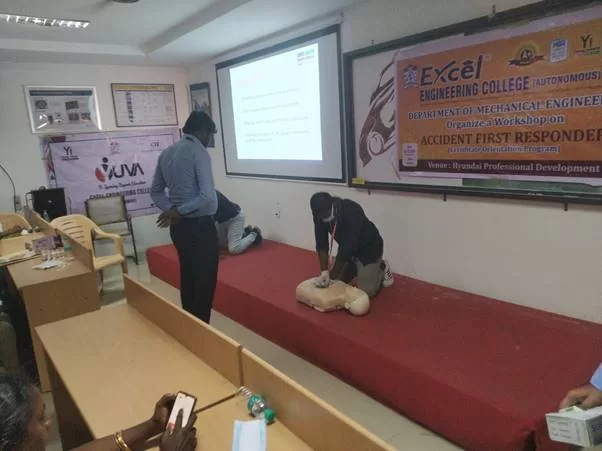

Accident First Responder

Date: 08.02.2024

Name of Coordinator: Dr.N.Venkatachalam Associate Professor/Mech

Mapping with POs,PSOs: PO – 6,7,8,9,12, PSO- 2

Number of Participants: 65 Students , 3 Staff Members

Description:

The Department of Mechanical Engineering organized a Workshop program on “Accident First Responder” to all the mechanical engineering stream students in Hyundai Development professional development seminar Hall on 08.02.2024 10.00 Am to 1.45 PM, during the session Mr.Venkatesan, AMRI, Chennai, greeted the students for the promoted new technologies and to adhere with the Accident First Responder to achieve greater miles stones in the future. This program was coordinately organized by all the mechanical department faculty members.

Report on Seminor

Investigations on Tool Life Enhancement of a Tungsten Carbide.

Our department has conducted a seminar on Investigations on tool life enhancement of a tungsten carbide. By Mr. N.Tamliselvan and Mr.K.Boopathy at smart class on (04-01-2020).

He explained about the design software available and the use of software’s in the industries. The jobs available based on the skills in software’s.

The followed by Mr.K.boopathy explained the various types of tools used in the present industries and the development of the product in the industries wide gates opened in industries to mechanical engineers.

Then the seminar was concluded at the final report on the Investigations on tool life enhancement of tungsten carbide trainings to our students and wide definition about the tools and handled the products.

Guest Lecture on United CADD Solution

Our MACHINE WARRIORZ ASSOCIATION of Mechanical Department are conducted Guest Lecture on United CADD Solution on 25-01-2020.

In that Mr.N.Tamilselvan and Mr.yuvaraj of our mechanical department has explained about the cadd importance and usage of cadd on the daily industries .

Then our guest who has explained the usage of cadd in designing of an product available in the industries with various slides, which was very useful to our students.

Then finally concluded the Seminar about CADD software in the Design and Manufacturing of Industries, shared placement opportunities in industries, and also offered courses for design (CAD / CAM software).

Code of Conduct

| Title of the Activity: Code of Conduct | Date: 03.07.2023 |

| Name of Coordinator: | 1. Dr.N.Natarajan HOD/Mech 2. Mr.V.Karthikeyan AP / Mech |

| Mapping with POs,PSOs: PO – 6,7,8,9,12, PSO- 2

| Number of Participants: 116 Students , 8 Staff Members

|

Description:

Department of Mechanical Engineering organized an awareness program on “Code of Conduct” to all the mechanical engineering stream students in Pavaiyammal Hall on 03.07.2023 10.00 am to 11.00 am, during the session Dr.N.Natarajan, Head of the Department greeted the students for the promoted semesters and give the speech roles and responsibilities of each students to adhere with the code of conduct to achieve greater miles stones in the future. This program was coordinately organized by all the mechanical department faculty members.

Anti-Plastic Campaign

| Title of the Activity: Anti-Plastic Campaign | Date: 28.07.2023 |

| Name of Coordinator: | Dr.N.Venkatachalam ASP/Mech |

| Mapping with POs,PSOs: PO – 6,7,8,9,12, PSO- 2

| Number of Participants: 131 Students , 3 Staff Members

|

Description:

Department of Mechanical Engineering organized a pollution awareness program on “Anti-Plastic Campaign” to all the mechanical engineering stream students in our college ground on 28.07.2023 3.30 pm to 04.45 pm, during the session Dr. N. Venkatachalam, Associate Professor greeted the students for the pollution awareness and responsibilities of each students to save the environment in the future. This program was coordinately organized by Dr. N. Venkatachalam, Associate Professor.

Alumni Guest Lecture

| Title of the Activity: Alumni Guest Lecture | Date: 24.07.2023 |

| Name of Coordinator: | 1. Mr.P.Nithiyanand, AP/Mech |

| Alumni : Ms.P.Mounika Topic : Role of Mechanical Engineers in Industry | Number of Participants: 116 Students , 8 Staff Members

|

Description:

Department of Mechanical Engineering organized an Alumni guest lecture on “Role of Mechanical Engineers in Industry” by our alumni Ms.P.Mounika on 24.07.2023 at A4 Block Pavaaiammal hall for Third year and Final year students of Mechanical Department. She is working as an Executive Trainee and Development Engineer in BMW project, TVS Motor Company, Hosur. The Head of the Department Dr.N.Natarajan Inaugurated the event. The Alumni has clearly explained the roll of Mechanical Freshers in the Core industries and the nature of work in each departments of Industry. The Alumni has been thanked and honored by the department Staff members and Alumni Coordinator Mr.P.Nithiyanand.

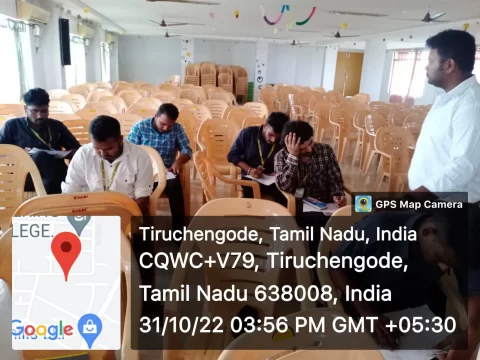

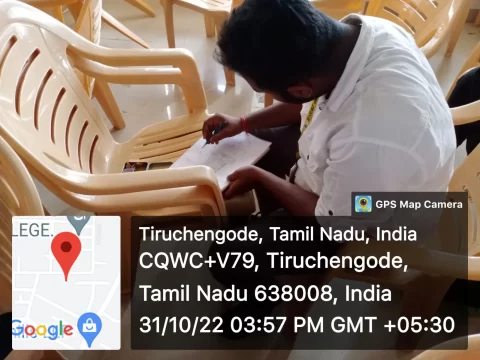

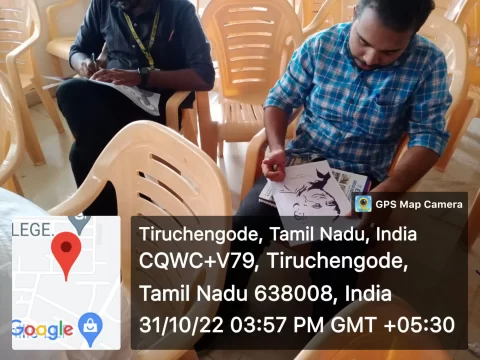

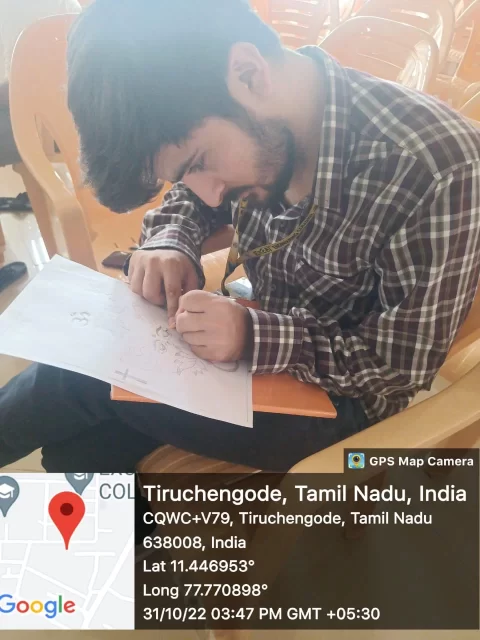

Harmony of our Indian Nation- In the memory Sardar Vallabhbhai Patel

Date of the Event : 31.10.2022 (Monday)

Time of the Event : 09.30 am to 04.00 pm

Venue : Pavaiyammal hall & Excel Technical Campus

Event Organizers

1. Run for Harmony

2. Debate on “Unity in Diversity – is strength or weakness?”

3. Drawing Competition – “World Peace”

Event Organizers

1. Mr.V.Karthikeyan AP /MECH /EEC

2. Mr.K.Arulkumar AP / MECH /EEC

Summary of the events:

The Unity day begins the event “Run for Harmony” introduced by Dr.S.Anbukaruppusamy, Director- Administration, Dr.S.Karthikeyani Director- Academics and initiated the run thru waving the flag by Dr.K.Bommanaraja Principal- EEC & Executive Director – Excel Group Institutions at the time of 10.20 am in Excel Technical campus with more than 150 participants from various departments along with their faculty members, students had completed their Unity run at 12.00 pm where they have started with full enthusiasm.

After the successful completion of run, students started their head start for Debate in Pavaiyammal hall in front of dignitaries Dr.N.Natarajan, Mr.K.Arulkumar, Mr.T.Karthikeyan and Mr.V.Karthikeyan, the debate become the healthy chat to understand the motto of the unity and discussed about both strength and weakness.

At last, the drawing competition begins with topic of world peace, in this student were eagerly participated to show the art and culture.

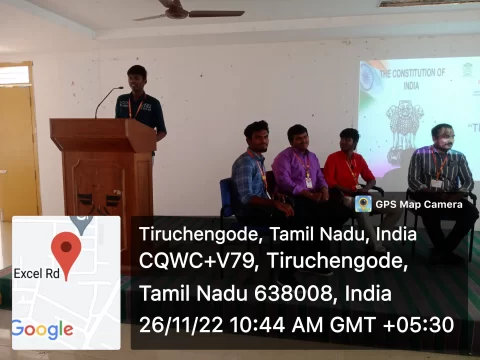

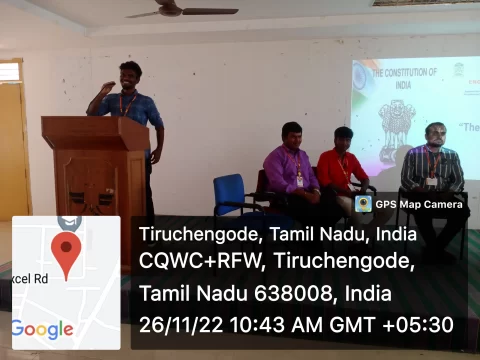

Constitution Day

Date of the Event : 26.11.2022 (Monday)

Time of the Event : 10.00 am to 11.00 am

Venue : Pavaiyammal hall

Event Organizers

1. Debate – “ The Law of Modern India”

2. Pledge

3. Online Quiz by MHRD

Event Organizers

1. Mr.V.Karthikeyan AP /MECH /EEC

2. Mr.M.Sambathkumar AP / MECH /EEC

2. Mr.N.Prithviraj AP/SFE/EEC

Summary of the events:

the main theme of the celebration of constitution day was briefed by Dr.N.Natrajan Head of the Department Mechanical and Safety and Fire Engineering, followed by Head of Department Mr.N.Prithiviraj explained the importance and role of constitution of India to young minds gathered to the celebration, after the oration students actively participated to pledge, in addition to that a debate titled “the Law of Modern India” has been conducted with Mr.K.Tamilan as jury member to that event

Finally, on consolidating the event Mr.V.Karthikeyan & Mr.M.Sambathkumar delivered the vote of thanks and motivated the students to take social responsibility for making the independent India better than now

At last, the drawing competition begins with topic of world peace, in this student were eagerly participated to show the art and culture.

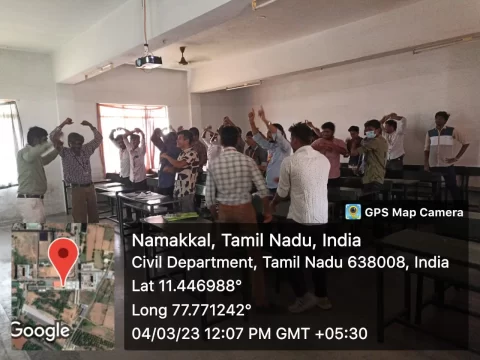

FDP on “Stress Management”

Date of the Event : 04.03.2023 (Saturday)

Time of the Event : 10.00 am to 11.00 am

Venue : Tiruvalluvar hall

Event Organizers

1. Dr.N.Venkatachalam ASP /MECH /EEC

2. Mr.V.Udayakumar AP /MECH /EEC

Summary of the events:

The event starts with welcoming of fellow faculty members continued with this Dr.N.Natarajan elaborated the details of awarding of Stress Management to the students and also introduced the latest announcements regarding the Stress Management program and its surplus opportunities to the student for getting the additional Stress Management in the open theme, Dr.K.Bommanna raja, Principal Carried over the event for considering the additional credit points for awarding the stress Management and the points from Both the directors were validated and appreciated by the fellow faculty members and the heads of the department.

Awareness Program on “Latest Software”

Date of the Event : 07.02.2023 (Saturday)

Time of the Event : 10.00 am to 11.00 am

Venue : Tiruvalluvar hall

Event Organizers

1. Dr.N.Venkatachalam ASP /MECH /EEC

2. Mr.M.Nandhakumar AP /MECH /EEC

Summary of the events:

The event starts with welcoming of fellow faculty members continued with this Dr.N.Natarajan elaborated the details of awarding of degree in various consideration to the students and also introduced the latest announcements regarding the Latest Software program and its surplus opportunities to the student for getting the additional Latest Software in the open theme, Dr.K.Bommanna raja, Principal Carried over the event for considering the additional credit points for awarding the Latest Software and the points from both the directors were validated and appreciated by the fellow faculty members and the heads of the department.

GHANDHI JAYANTHI as ” NON VIOLENCE DAY “

Summary of the event: “NON VIOLENCE DAY”

Resource person Dr.N.Natrajan, HOD/Mech, Excel Engineering College Number of Participants: 105

Content Covered: The mechanical Engineering students has celebrated NON VIOLENCE DAY on 06.10.2022 chief guest of the function Dr.N.Natrajan addressed our students about Mahatma

Gandhi. The International Day of Non-Violence is observed on 2 October, the birthday of Mahatma Gandhi, leader of the Indian independence movement and pioneer of the philosophy and strategy of non-violence. “Non-violence is the greatest force at the disposal of mankind. It is mightier than the mightiest weapon of destruction devised by the ingenuity of man”.

Design Contest on Bi-Cycle

Date of the Event : 04.02.2023 (Saturday)

Time of the Event : 11.30 am to 1.00 pm

Venue : Smart class room, A4 Building, Department of Mechanical Engineering

List of Events : Alumni Guest Lecture

Event Organizers

1. Dr. M. Venkatesan, AP / MECH /EEC

2. Mr. S. Sabeer Ushen AP / MECH /EEC

Summary of the events:

The Industry Guest Lecture on ‘Career Prospects for Mechanical Engineers’ on 04th February 2023 starts at 11.30 am with welcome address by Dr.N.Natrajan, Prof and Head of Mechanical Engineering. The guest is also an alumni and member of BOS of Department of Mechanical Engineering.

The event kick started by Resource Person Mr. Karthikeyan Chandrasekaran, Customer support analyst of Ultramain Software India PVT Ltd talked about his memories and experiences in and about EEC. The current and future prospects for the mechanical engineers were discussed with the students. The importance of knowing fundamentals and application of that principles in latest software were explained. The job opportunities in core and software fields are known by students after discussion. After completion of degree, Higher studies and abroad studies with scholarship were encouraged.

A wide range of discussions including personal thoughts and doubts were discussed in the alumni cum industry lecture. From attending the event, the students got motivated and being ready to face the new job challenges.

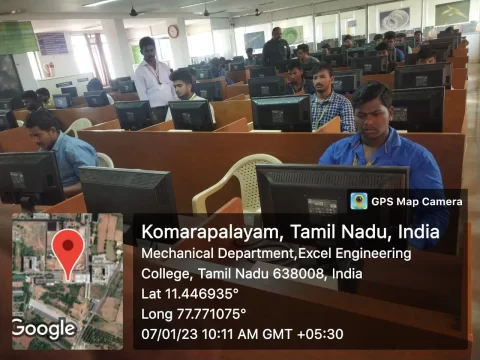

Design Contest on Bi-Cycle

Date of the Event : 07.01.2023

Time of the Event : 10.00 am to 11.00 am

Venue : CADD CENTER

Event Organizers

1. Mr.V.Karthikeyan AP /MECH /EEC

2. Mr. K.Arulkumar AP / MECH /EEC

Summary of the events:

The main theme of the event was briefed by Dr.N.Natrajan Head of the Department Mechanical explained the rules and regulation of the open design contest to the young students assembled for the competition, after the introductory session students actively participated in design contest “Bi-Cycle Design”

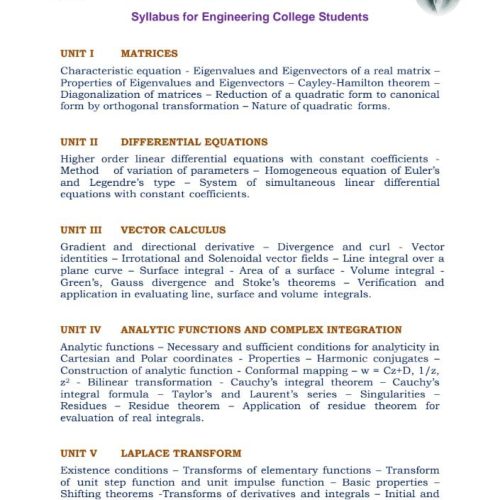

Value Added Courses

Research & Development

Faculty Eligible for Guiding Ph.D. Scholars

| S.No | Name of the Faculty | Area of Specialization | Year of Registration for Guideship | University |

|---|---|---|---|---|

| Academic Year 2016-17 | ||||

| 1 | Dr. V. K. Shunmughanaathan | Mechanical Scheduling | 2009 | Anna University |

| 2 | Dr.G.Nallakumarasamy | Manufacturing | 2012 | Anna University |

| Academic Year 2017-18 | ||||

| 1 | Dr. V. K. Shunmughanaathan | Mechanical Scheduling | 2009 | Anna University |

| 2 | Dr.G.Nallakumarasamy | Manufacturing | 2012 | Anna University |

| Academic Year 2018-19 | ||||

| 1 | Dr. V. K. Shunmughanaathan | Mechanical Scheduling | 2009 | Anna University |

| 2 | Dr.G.Nallakumarasamy | Manufacturing | 2012 | Anna University |

| Academic Year 2019-20 | ||||

| 1 | Dr. V. K. Shunmughanaathan | Mechanical Scheduling | 2009 | Anna University |

| 2 | Dr.G.Nallakumarasamy | Manufacturing | 2012 | Anna University |

| Academic Year 2020-21 | ||||

| 1 | Dr. N.Natarajan | Composite Material | 2008 | Anna University |

| 2 | Dr. B.K. Gnanavel | Cable Mechanics | 2012 | Anna University |

| Academic Year 2021-22 | ||||

| 1 | Dr. N.Natarajan | Composite Material | 2008 | Anna University |

| 2 | Dr. B.K. Gnavel | Cable Mechanics | 2012 | Anna University |

| 3 | Dr. R.Vinoth | Heat Transfer, Heat Exchanger | 2021 | Anna University |

| Academic Year 2022-23 | ||||

| 1 | Dr. N.Natarajan | Composite Material | 2008 | Anna University |

| 2 | Dr. R. Vinoth | Heat Transfer, Heat Exchanger | 2021 | Anna University |

| 3 | Dr. M. Venkatesan | Heat Transfer, Energy and Buildings, Waste Management System | 2022 | Anna University |

| Academic Year 2023-24 | ||||

| 1 | Dr. M. Kathiresan | Composite Materials, Metal Matrix, Mechanical Properties, Wear | 2011 | Anna University |

| 2 | Dr. R. Vinoth | Heat Transfer, Heat Exchanger | 2021 | Anna University |

| 3 | Dr. M. Venkatesan | Heat Transfer, Energy and Buildings, Waste Management System | 2022 | Anna University |

| Academic Year 2024-25 | ||||

| 1 | Dr. M. Kathiresan | Composite Materials, Metal Matrix, Mechanical Properties, Wear | 2011 | Anna University |

| 2 | Dr. P. Karunakaran | Sand Casting, EDM, ECM, Composite Materials | 2016 | Anna University |

| 3 | Dr. R. Vinoth | Heat Transfer, Heat Exchanger | 2021 | Anna University |

| 4 | Dr. M. Venkatesan | Heat Transfer, Energy and Buildings, Waste Management System | 2022 | Anna University |

| 5 | S. Karthick | Welding, Optimization, Manufacturing Process, Materials | 2023 | Anna University |

Book Publication

R & D Proposals Details

| S.No | Academic Year | Name of the Scheme | Name of the Faculty | Title of the proposal | Fund Request |

| 1 | 2020-21 | DST-FIST | Mr.M.Sambathkumar | Advanced Thermal Engineering Laboratory | 75,00,000 |

| 3 | 2020-21 | SERB | Mr. R. RAJARAJAN | Advanced Precision Irrigation Systems in Digital Farming | 1,65,000 |

| 4 | 2020-21 | AICTE | Dr. K. Boopathy Mr. M.Sampathkumar | Recent trends in mechanical sciences robotic and automation | 3,00,000 |

| 5 | 2020-21 | AICTE-RPS | Dr. K. Boopathy | Investigation on Tool life enhancement of Tungsten Carbide | 226000 |

| 6 | 2020-21 | DIT | Mr. Praveen & Selvakumar | Awareness Programme on Post Harvest | 49000 |

| 7 | 2020-21 | TNSCST | Dr.N.Venkatachalam | Fabrication on Sustainable Energy House through Green Power Techniques for Eco – Socio Environment | 10000 |

| 8 | 2020-21 | TNSCST | N.Tamilselvan | Design and Fabrication of Coconut Husk Unloading Machine from Goods Vehicle | 10000 |

| 9 | 2020-21 | TNSCST | M.Sambathkumar | Design & Fabrication of Rope fully | 10000 |

| 10 | 2020-21 | TNSCST | D.Alagesan | Design and Fabrication of Double pass Solar Heat Exchanger | 10000 |

| 11 | 2020-21 | TNSCST | S.Ananthakumar | Design and Fabrication of Agriculture sprayer, Plougher and wetter with cutter | 10000 |

| 12 | 2020-21 | TNSCST | M.Nanthakumar | Foot Step power generation using Rack & Pinion | 10000 |

| 13 | 2020-21 | TNSCST | Dr. K.Boopathy | Design and Fabrication of Paddy Planting Machine | 10000 |

| 14 | 2020-21 | TNSCST | N.PrithiviRaj | Conventional Refrigeration System by using PCM | 10000 |

| 15 | 2020-21 | AICTE | Dr. N. Natarajan D. Alagesan | IDEA LAB | 1,09,85,850 |

| 16 | 2020-21 | SERB-Core Research Grant | Dr.N.Venkatachalam | Excel Innovation & Research Incubation Centre (EIRIC) ( File No: CRG/2021/000016 ) | 1,73,64,601 |

| 17 | 2020-21 | SERB- START UP | Dr.K.Boopathy & M.SampathKumar | Investigations on Tool Life Enhancement of a Tungsten Carbide Insert | 30,17,428 |

| 18 | 2020-21 | AICE-ATAL | Dr.N.Venkatachalam | Fabrication on Sustainable Energy House through Green Power Techniques for Eco – Socio Environment | 93,000 |

| 19 | 2020-21 | SERB-Core Research Grant | Dr.R.Vinoth | Effective Thermal ManagementSystem in Electricc Vehicle PowerConverters using Oblique FinnedHexagonal Microchannel with Hybrid NanoFluid | 37,46,096 |

| 20 | 2020-21 | SERB-SUPRA | Dr.S.Balakrishnan & Dr. R.Vinoth | Investigation of Structural intergrity of shape iperfect pipebends under different mechanical loadings using 3DScanner and ABAQUS nonlinear software package | 25,00,551 |

| S.No | Name of the Student members | Name of the Guide | Title of Project | Name of the Sponsored Industry | Sponsored Amount (Rs.) |

|---|---|---|---|---|---|

| Academic Year 2020-21 | |||||

| 1 | 1.Mahesh Kumar. G 2.Elbin George 3.Dinesh Kumar. R | Mr. M. Nandhakumar | Future development on Drone | Rice Mills | 2,00,000 |

| 2 | 1.Vignesh. R 2.Abinesh. V 3.Thushar. T | Mr. P.P. Gowtham | Ford Eco Sport vehicle Car | Ford India Private Limited, Tamilnadu | 12,86,972 |

| Total Rs. | 14,86,972 | ||||

Future development on Drone-Gallery

Industry Institute Interaction

Industrial Visit

| S. No. | Organization with Which MoU is signed | Name of the Industry/Institution/Cooperate house | Year of Signing MoU | Duratiom |

|---|---|---|---|---|

| 1. | We win Finishing Equipment PVT LTD | Excel Engineering College | 2019 | Life Time |

| 2. | Nouveaux Industries PVT LTD | Excel Engineering College | 2019 | 5 years |

| 3. | Euro Cast Engineering | Excel Engineering College | 2019 | 5 years |

| 4. | SIM InfoSystems PVT LTD | Excel Engineering College | 2019 | 5 years |

| 5. | Sakthi AutoComponents Limited | Excel Engineering College | 2019 | 3 years |

| 6. | Vijay Agro Pipe line Industies | Excel Engineering College | 2019 | 5 years |

| 7. | Wonjin autoparts india private limited, | Excel Engineering College | 2020 | Lifetime |

JSW Namelist III YR (JSW STEEL INDIA LIMITED)

| S.No | Student Name |

|---|---|

| 1 | Arun.R |

| 2 | Arunkumar.A |

| 3 | Balaji.M |

| 4 | Barath.M |

| 5 | Boopathi.G |

| 6 | Balaganesh.R |

| 7 | Dinakar.S |

| 8 | Dinesh.P |

| 9 | Dinakaran.P |

| 10 | Gopinath.V |

| 11 | Gunasekar.S |

| 12 | Hariprasath.S |

| 13 | Jeeva.R |

| 14 | Kanagaraj.M |

| 15 | Karthik.S |

| 16 | Karthikaivel.S |

| 17 | Kathirvel.S |

| 18 | Loganand.J |

| 19 | Mathan Raj.M |

| 20 | Praveen.M |

NAB Name List IV YR (CRAYDESI PVT LIMITED)

| S.No | Student Name |

|---|---|

| 1 | Prabin Mahato |

| 2 | Pankaj Yadav |

| 3 | Motifansari |

| 4 | Nirankumar |

| 5 | Nestline Anto Johny |

| 6 | Iuto.Y. Shohe |

| 7 | Habib Dhuniya |

| 8 | Manjay Kumar |

| 9 | Niraj Kumaryadav |

| 10 | Nirankumar Haobam |

Details of MoU Signed

| S. No. | Organization with Which MoU is signed | Name of the Industry/Institution/Cooperate house | Year of Signing MoU | Duration |

|---|---|---|---|---|

| 1. | We win Finishing Equipment PVT LTD | Excel Engineering College | 2019 | Life Time |

| 2. | Nouveaux Industries PVT LTD | Excel Engineering College | 2019 | 5 years |

| 3. | Euro Cast Engineering | Excel Engineering College | 2019 | 5 years |

| 4. | SIM InfoSystems PVT LTD | Excel Engineering College | 2019 | 5 years |

| 5. | Sakthi AutoComponents Limited | Excel Engineering College | 2019 | 3 years |

| 6. | Vijay Agro Pipe line Industies | Excel Engineering College | 2019 | 5 years |

| 7. | Wonjin autoparts india private limited, | Excel Engineering College | 2020 | Lifetime |

Industry Collabration

| S.No. | Name of the Industry | Purpose |

|---|---|---|

| 1 | Nouveaux Industries Pvt, Ltd -Kangayam | Project , Placement, Internship, Industrial Visit |

| 2 | EURO Cast Engineering-Annur-Coimbatore | Project , Placement, Internship, Industrial Visit |

| 3 | SIM InfoSystems Pvt Ltd-Chennai | Project , Placement, Internship, Industrial Visit |

| 4 | Sakthi Auto Component Limited – Uthukuli | Project , Placement, Internship, Industrial Visit |

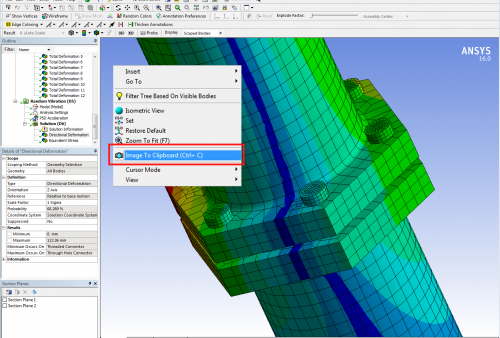

Workshop on “On-Board Diagnostics of Vehicles”

Date of the Event : 04.03.2023 (Saturday)

Time of the Event : 10.00 am to 4.00 pm

Venue : Hyundai Lab

List of Events

1. Workshop on “On board Diagnostics of Vehicles”.

Event Organizers

1. Mr.R.Premraj, AP /MECH /EEC

2. Mr.M.Sambathkumar AP / MECH /EEC

Summary of the events:

Hyundai Professional Development Centre-Excel Technical Campus organizes a Workshop on “Vechicle Aerodynamics” on 04th March 2023 starts at 10.00 am with welcome address by Dr.N.Venkatachalam of Mechanical Engineering. in this, the event kick started by Mr.M.Sambathkumar,AP/Mech & Mr.R.Premraj AP/Mech and they talks about basics about “Automobile Diagnostics system using OBD Kit ”.

Mr.R.Premraj & Mr.M.Sambathkumar briefing about Perform and analyze results from compression, oil pressure, vacuum, cylinder leakage, fuel pressure and cooling system checking with aid of OBD Kit .

They Taught how to Inspect engine assembly and repair wear, noise, leaks from oil, coolant and fuel and determine necessary action for repair also talks about engine disassembly and reassembly methods to participants.

Number of Participants : Staffs: 3, Students: 40

Induction Programme on “Automotive System Service”

| Name of the event | : Induction Programme on “Automotive System Service” |

| Even timing | : 10.00 am to 04.00 pm |

| Department | : Mechanical Engineering |

| Name of the organiser (Faculty member who organized the event) with the designation | : 1. Mr.M.Sambathkumar AP / MECH 2.Mr.R.Premraj ,AP/Mech

|

| Name and Roll number of the students who has participated in the event | : Name list Attached (50 Students) |

| Expert member Details | |

| Name of the Trainer(s) | : Mr.M.Sambathkumar & Mr.R.Premraj |

| Designation | : Assistant Professor(s) |

| Name of organisation | : Excel Engineering College |

| Address | : NH 544 Salem-Kochin Highways,Pallakkapalayam,Komarapalayam,Namakkal-637303. |

| Email id | : sambathkumarkm@gmail.com, premrajmechanical@gmail.com |

| Mobile number | : 9994426296,7010026760 |

Event Description

Induction Programme on “Automotive System Service” on 08th October 2022 starts at 10.00 am with welcome address by Dr.N.Tamilselvan of Mechanical Engineering. in this, the event kick started by Mr.M.Sambathkumar,AP/Mech & Mr.R.Premraj AP/Mech and they talks about basics about “Automobiles and Engine Management system in automotive applications”.

A wide range of subjects are taught in Automobile engineering which include mobility design and aesthetics, Automotive materials, Automotive electrical and electronics, computer-aided vehicle design, vehicle maintenance, electric mobility, Thermodynamics, Engineering mechanics, Manufacturing Technology, Fuels etc.,also talks about development of passenger cars, trucks, buses, motorcycles, or off-road vehicles.

Moreover this Training helps to improve their skills on automobiles and on completion of this event students are really impressed and interacted with the guest and cleared their domain doubts.

Finally Feedbacks are get it from Participants and taking some valuable suggestions from participants side.

Participants List

| S. No | Roll Number | Reg. Number | Student Name |

| 1 | 21LME062 | 730920114301 | AJAY.R |

| 2 | 21LME063 | 730920114302 | ANDRO JULIES |

| 3 | 21LME064 | 730920114303 | BARATH.S.E |

| 4 | 21LME065 | 730920114304 | BARATH.V.S |

| 5 | 21LME066 | 730920114305 | BHAVANTH M |

| 6 | 21LME067 | 730920114306 | BIBIN.C.VARGHESE |

| 7 | 21LME068 | 730920114307 | BOOMILAN.M |

| 8 | 21LME069 | 730920114308 | DEEPAK.R |

| 9 | 21LME070 | 730920114309 | DEEPAN.K |

| 10 | 21LME071 | 730920114310 | DEEPANCHAKRAVARTHI.S |

| 11 | 21LME072 | 730920114311 | DHAMODHARAN.D |

| 12 | 21LME073 | 730920114312 | DHINESH.V |

| 13 | 21LME074 | 730920114313 | GOKULRISHI.Y |

| 14 | 21LME075 | 730920114314 | GOPI.M |

| 15 | 21LME076 | 730920114315 | GUNA.R |

| 16 | 21LME077 | 730920114316 | JAGADEESHKUMAR.B |

| 17 | 21LME078 | 730920114317 | JEEVARAGAVAN.K |

| 18 | 21LME079 | 730920114318 | JIBIN JOHN |

| 19 | 21LME081 | 730920114319 | KOWSALYA.P |

| 20 | 21LME082 | 730920114320 | KURALARASAN.S |

| 21 | 21LME083 | 730920114321 | MAHENDRAN.P |

| 22 | 21LME084 | 730920114322 | MAIVIZHISELVAN.R |

| 23 | 21LME085 | 730920114323 | MANIKANDAN.D |

| 24 | 21LME086 | 730920114324 | MANOJKUMAR.R |

| 25 | 21LME087 | 730920114325 | MUKESH BOOPATHI M |

| 26 | 21LME088 | 730920114326 | MURUGASEN.S |

| 27 | 21LME089 | 730920114327 | NANJIL MUKILAN.C.D |

| 28 | 21LME090 | 730920114328 | NIKHIL.R |

| 29 | 21LME091 | 730920114329 | PONRAJ.G |

| 30 | 21LME093 | 730920114330 | PRADEEP.G |

| 31 | 21LME094 | 730920114331 | PREMKUMAR.V |

| 32 | 21LME095 | 730920114332 | RAJKUMAR.B |

| 33 | 21LME096 | 730920114333 | RANDEEP.S |

| 34 | 21LME097 | 730920114334 | RANJITHKUMAR.S |

| 35 | 21LME099 | 730920114335 | RISHIKUMAR.P |

| 36 | 21LME100 | 730920114336 | SAKTHEESWARAN.M |

| 37 | 21LME101 | 730920114337 | SALAIKAVIN.T |

| 38 | 21LME102 | 730920114338 | SANJEEV.V |

| 39 | 21LME103 | 730920114339 | SANTHOSH.P |

| 40 | 21LME104 | 730920114340 | SATHISH KUMAR.S |

| 41 | 21LME105 | 730920114341 | SATHIYARAJ.A |

| 42 | 21LME106 | 730920114342 | SELVARAJU.S |

| 43 | 21LME107 | 730920114343 | SOUNDHAR.S |

| 44 | 21LME108 | 730920114344 | SOWNTHARYA.P |

| 45 | 21LME109 | 730920114345 | SREEKANTH.R |

| 46 | 21LME110 | 730920114346 | SRIHARIHARAN.S |

| 47 | 21LME111 | 730920114347 | SUBASH CHANDRA.S.R |

| 48 | 21LME113 | 730920114348 | SUBASH.R |

| 49 | 21LME114 | 730920114349 | SUDHARSAN.P |

| 50 | 21LME115 | 730920114350 | SURESH.S |

| 51 | 21LME116 | ,730920114351 | THANUSH.S |

| 52 | 21LME117 | 730920114352 | UDHAYAKUMAR.V |

| 53 | 21LME118 | 730920114353 | VIGNESH.E |

| 54 | 21LME119 | 730920114354 | VIGNESHWARAN.V |

| 55 | 21LME121 | 730920114355 | SARATH KRISHNA.K |

| 56 | 20ME001 | 730920114001 | ABHISHEK KUMAR |

| 57 | 20ME002 | 730920114002 | ABHISHEK KUMAR |

| 58 | 20ME003 | 730920114003 | ADITYA JAISWAL |

| 59 | 20ME005 | 730920114005 | AMIT KUMAR |

| 60 | 20ME006 | 730920114006 | ANIKET KUMAR SINGH |

| 61 | 20ME007 | 730920114007 | ANIL KUMAR RAM |

| 62 | 20ME008 | 730920114008 | ARAVINTH KUMAR.V |

| 63 | 20ME018 | 730920114018 | KARTHIK.M |

| 64 | 20ME024 | 730920114024 | MANJEET KUMAR |

| 65 | 20ME025 | 730920114025 | MATHAN RAJ.S |

| 66 | 20ME026 | 730920114026 | MD GAYASUDDIN |

| 67 | 20ME027 | 730920114027 | MD HEDAYATULLAH |

| 68 | 20ME028 | 730920114028 | MD IRSHAD |

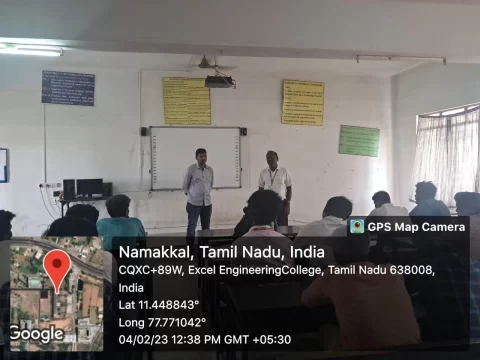

Workshop on “Vehicle Aerodynamics”

Date of the Event : 04.02.2023 (Saturday)

Time of the Event : 10.00 am to 4.00 pm

Venue : Hyundai Lab

List of Events

1. Workshop on Vehicle Aerodynamics.

Event Organizers

1. Mr.T.Karthikeyan, AP /MECH /EEC

2. Mr.M.Sambathkumar AP / MECH /EEC

Summary of the events:

Hyundai Professional Development Centre-Excel Technical Campus organizes a Workshop on “Vechicle Aerodynamics” on 04th February 2023 starts at 10.00 am with welcome address by Dr.N.Venkatachalam of Mechanical Engineering. in this, the event kick started by Mr.M.Sambathkumar,AP/Mech & Mr.T.Karthikeyan AP/Mech and they talks about basics about “Automobiles and Engine Management system in automotive applications”.

A wide range of subjects are taught in Automobile engineering which include mobility design and aesthetics, Automotive materials, Automotive electrical and electronics, computer-aided vehicle design, vehicle maintenance, electric mobility, Thermodynamics, Engineering mechanics, Manufacturing Technology, Fuels etc.,also talks about development of passenger cars, trucks, buses, motorcycles, or off-road vehicles.

Number of Participants : Staffs: 2, Students: 30

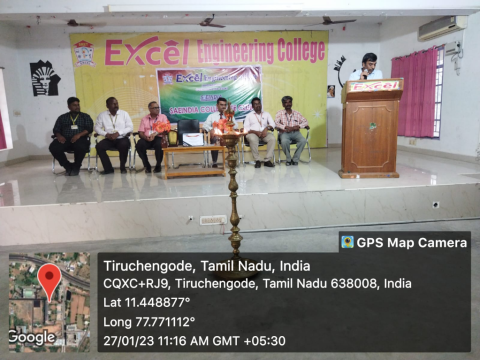

“Guest Lecture on Recent Advances in Automotive Engineering”

Date of the Event : 27.01.2023 (Saturday)

Time of the Event : 10.00 am to 1.00 pm

Venue : APJ Hall

List of Events

1. Inaugural on SAEINDIA Collegiate Club.

2. Recent Advances in Automotive Engineering

Event Organizers

1. Mr.R.Premraj, AP /MECH /EEC

2. Mr.M.Sambathkumar AP / MECH /EEC

Summary of the events:

The Guest Lecture on “Recent Advances in Automotive Engineering“ is a branch of applied science, which deals with designing, developing, and manufacturing ground vehicles. Vehicle development is an interdisciplinary optimization problem subject to many design criterions, which are often conflict with each other. In the development of a new vehicle, major design criterions are defined due to fuel consumption, vehicle safety, crashworthiness, durability, ride comfort, handling behaviors, ergonomics, aerodynamics and NVH concepts. The competitive nature of automotive industry forces original equipment manufacturers (OEMs) to make critical decisions among these design parameters and also discussed with Electric vehicles can be classified into three types as tabulated in Table 1: hybrid electric vehicles (HEVs), plug-in electric vehicles (PHEVs) and full electric vehicles (FEVs). HEVs are equipped with an internal combustion engine (ICE) and an electric motor. In these vehicles, the primary source of energy is an ICE that runs on fossil or alternative fuels

A wide range of subjects are taught in Automobile engineering which include mobility design and aesthetics, Automotive materials, Automotive electrical and electronics, computer-aided vehicle design, vehicle maintenance, electric mobility, Fuels etc. Also talks about development of passenger cars, trucks, buses, motorcycles, or off-road vehicles.

Number of Participants : Staffs: 2, Students: 200

“Workshop”

Date of the Event : 21.01.2023 (Saturday)

Time of the Event : 10.00 am to 4.00 pm

Venue : Hyundai Lab

List of Events : 1. Workshop on Vehicle Health Monitoring and Maintenance.

Event Organizers

1. Mr.R.Premraj, AP /MECH /EEC

2. Mr.M.Sambathkumar AP / MECH /EEC

Summary of the events:

The Workshop on “Vechicle Health Monitoring and Maintenance” on 21th January 2023 starts at 10.00 am with welcome address by Dr.N.Venkatachalam of Mechanical Engineering. in this, the event kick started by Mr.M.Sambathkumar,AP/Mech & Mr.R.Premraj AP/Mech and they talks about basics about “Automobiles and Engine Management system in automotive applications”.

A wide range of subjects are taught in Automobile engineering which include mobility design and aesthetics, Automotive materials, Automotive electrical and electronics, computer-aided vehicle design, vehicle maintenance, electric mobility, Thermodynamics, Engineering mechanics, Manufacturing Technology, Fuels etc.,also talks about development of passenger cars, trucks, buses, motorcycles, or off-road vehicles.

Number of Participants : Staffs: 2, Students: 30

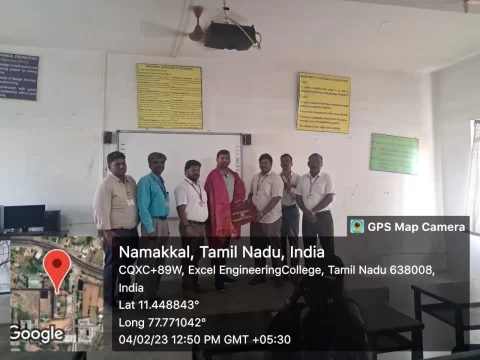

Workshop on “On-Board Diagnostics of Vehicles”

Date of the Event : 04.03.2023 (Saturday)

Time of the Event : 10.00 am to 4.00 pm

Venue : Hyundai Lab

List of Events : 1.Workshop on “On board Diagnostics of Vehicles”.

Event Organizers

1. Mr.R.Premraj, AP /MECH /EEC

2. Mr.M.Sambathkumar AP / MECH /EEC

3. Mr.T.Karthikeyan AP/MECH/EEC

Summary of the events:

Hyundai Professional Development Centre-Excel Engineering College organizes a Workshop on “On board Diagnostics of Vehicles” on 04th March 2023 starts at 10.00 am with welcome address by Dr.N.Venkatachalam of Mechanical Engineering. in this, the event kick started by Mr.M.Sambathkumar,AP/Mech & Mr.R.PREMRAJ AP/Mech and they talks about basics about “Automobile Diagnostics system using OBD Kit ”.

Mr.R.PREMRAJ & Mr.M.Sambathkumar briefing about Perform and analyze results from compression, oil pressure, vacuum, cylinder leakage, fuel pressure and cooling system checking with aid of OBD Kit .

They taught how to inspect engine assembly and repair wear, noise, leaks from oil, coolant and fuel and determine necessary action for repair also talks about engine disassembly and reassembly methods to participants.

Number of Participants : Staffs: 3, Students: 40

Faculty

Faculty Details AY 2024-25

| S.No | Name of the Faculty Member | Degree (highest degree) | Designation | Specialization |

| 1. | Dr. M. Kathiresan | Ph.D | Professor & Head | Production Engineering |

| 2. | Dr. R. Vinoth | Ph.D | Professor | Thermal Engineering |

| 3. | Dr. P. Karunakaran | Ph.D | Professor | Production Engineering |

| 4. | Dr. M. Venkatesan | Ph.D | Associate Professor | Thermal Engineering |

| 5. | Dr. E.R. Sivakumar | Ph.D | Associate Professor | Engineering Design |

| 6. | Dr. V. Seshadhri | Ph.D | Assistant Professor | Manufacturing Engineering |

| 7. | Dr. S. Karthick | Ph.D | Assistant Professor | Production Engineering |

| 8. | Dr. G. Sathiyamoorthy | Ph.D | Assistant Professor | Production Engineering |

| 9. | Mr. S. S. Jayaraman | M.E | Assistant Professor | Production Engineering |

| 10. | Mr. D. Alagesan | M.E | Assistant Professor | Engineering Design |

| 11. | Mr. M. Sambath Kumar | M.E | Assistant Professor | Engineering Design |

| 12. | Mr. M. Nandhakumar | M.E | Assistant Professor | Engineering Design |

| 13. | Mr. N. Prithiviraj | M.E | Assistant Professor | Engineering Design |

| 14. | Mr. M. Dinesh kumar | M.E | Assistant Professor | Engineering Design |

| 15. | Mr. N. Selvakumar | M.E | Assistant Professor | Engineering Design |

| 16. | Mrs. K. K. Megavarthini | M.E | Assistant Professor | Computer Integrated Manufacturing |

| 17. | Mr. K. Arul Kumar | M.E | Assistant Professor | Computer-Aided Design |

| 18. | Mr. J. Daarathi Nishanth | M.E | Assistant Professor | Thermal Engineering |

| 19. | Dr. K. Boopathy | Ph.D | Associate Professor | Industrial Engineering |

| 20. | Mr. P. Nithiyanand | M.E | Assistant Professor | Energy Engineering |

| Visiting Faculty | ||||

| 21. | Mr. P. Jagadeeswaran | M.E | The Manager,(Service &Technical Trainer) Brilliant TVS, Mandaveli Chennai-28 | Engineering Design |

Faculty Details AY 2023-24

| S.No | Name of the Faculty Member | Degree (highest degree) | Designation | Specialization |

| 1. | Dr. M. Kathiresan | Ph.D | Professor & Head | Production Engineering |

| 2. | Dr. R. Vinoth | Ph.D | Professor | Thermal Engineering |

| 3. | Dr. N. Venkatachalam | Ph.D | Associate Professor | CAD/CAM |

| 4. | Dr. E.R. Sivakumar | Ph.D | Associate Professor | Engineering Design |

| 5. | Dr. N. Tamilselvan | Ph.D | Assistant Professor | Manufacturing Engineering |

| 6. | Dr. M. Venkatesan | Ph.D | Assistant Professor | Thermal Engineering |

| 7. | Mr. S. S. Jayaraman | M.E | Assistant Professor | Production Engineering |

| 8. | Mr. M. Srikanth | M.E | Assistant Professor | Thermal Engineering |

| 9. | Mr. D. Alagesan | M.E | Assistant Professor | Engineering Design |

| 10. | Mr. P. Praveen | M.E | Assistant Professor | Engineering Design |

| 11. | Mr. V. Karthikeyan | M.E | Assistant Professor | Engineering Design |

| 12. | Mr. T.M. Sakthi muruga | M.E | Assistant Professor | CAD/CAM |

| 13. | Mr. M. Sambath Kumar | M.E | Assistant Professor | Engineering Design |

| 14. | Mr. M. Nandhakumar | M.E | Assistant Professor | Engineering Design |

| 15. | Mr. N. Prithiviraj | M.E | Assistant Professor | Engineering Design |

| 16. | Mr. N. Selvakumar | M.E | Assistant Professor | Engineering Design |

| 17. | Mr. M. Dineshkumar | M.E | Assistant Professor | Engineering Design |

| 18. | Mrs. K. K. Megavarthini | M.E | Assistant Professor | Computer Integrated Manufacturing |

| 19. | Dr. K. Boopathy | Ph.D | Associate Professor | Industrial Engineering |

| 20. | Mr. P. Nithiyanand | M.E | Assistant Professor | Energy Engineering |

| Visiting Faculty | ||||

| 21. | Mr. P. Jagadeeswaran | M.E | The Manager,(Service &Technical Trainer) Brilliant TVS, Mandaveli Chennai-28 | Engineering Design |

Faculty Details AY 2022-23

| S.No | Name of the Faculty Member | Degree (highest degree) | Designation | Specialization |

| 1. | Dr. N. Natarajan | Ph.D | Professor & Head | Production Engineering |

| 2. | Dr. N. Venkatachalam | Ph.D | Associate Professor | CAD/CAM |

| 3. | Dr. R. Vinoth | Ph.D | Associate Professor | Thermal Engineering |

| 4. | Dr. E.R. Sivakumar | Ph.D | Associate Professor | Engineering Design |

| 5. | Dr. N. Tamilselvan | Ph.D | Assistant Professor | Manufacturing Engineering |

| 6. | Dr. M. Venkatesan | Ph.D | Assistant Professor | Thermal Engineering |

| 7. | Mr. S. S. Jayaraman | M.E | Assistant Professor | Production Engineering |

| 8. | Mr. G. Ramamoorthi | M.E | Assistant Professor | Thermal Engineering |

| 9. | Mr. D. Alagesan | M.E | Assistant Professor | Engineering Design |

| 10. | Mr. M. Srikanth | M.E | Assistant Professor | Thermal Engineering |

| 11. | Mr. P. Praveen | M.E | Assistant Professor | Engineering Design |

| 12. | Mr. V. Karthikeyan | M.E | Assistant Professor | Engineering Design |

| 13. | Mr. M. Sambath Kumar | M.E | Assistant Professor | Engineering Design |

| 14. | Mr. M. Nandhakumar | M.E | Assistant Professor | Engineering Design |

| 15. | Mr. T.M. Sakthi muruga | M.E | Assistant Professor | CAD/CAM |

| 16. | Mr. V. Udhayakumar | M.E | Assistant Professor | Engineering Design |

| 17. | Mr. N. Prithiviraj | M.E | Assistant Professor | Engineering Design |

| 18. | Mr. N. Selvakumar | M.E | Assistant Professor | Engineering Design |

| 19. | Mr. S. Anandhakumar | M.E | Assistant Professor | Engineering Design |

| 20. | Mr. M. Dineshkumar | M.E | Assistant Professor | Engineering Design |

| 21. | Mr. V. Prasanna kumar | M.E | Assistant Professor | Plastic Technology |

| 22. | Mr. D.S. Gokulraj | M.E | Assistant Professor | Engineering Design |

| 23. | Mr. R. Premraj | M.E | Assistant Professor | Engineering Design |

| 24. | Dr. K. Boopathy | Ph.D | Associate Professor | Industrial Engineering |

| 25. | Mr. P. Nithiyanand | M.E | Assistant Professor | Energy Engineering |

| 26. | Mr. T. Mohanasundaram | M.E | Assistant Professor | Thermal Engineering |

| Visiting Faculty | ||||

| 27. | Mr. P. Jagadeeswaran | M.E | The Manager,(Service &Technical Trainer) Brilliant TVS, Mandaveli Chennai-28 | Engineering Design |

Faculty

| Excel Engineering College (Autonomous) | |||

| Department of Mechanical Engineering | |||

| 2023-24 Name list | |||

| S.NO | Name | Qualification | Designation |

| 1 | Dr.M.Kathiresan | Ph.D | Head / Professor |

| 2 | Dr.N.Venkatachalam | Ph.D | Associate Professor |

| 3 | Dr.A.Sivakumar | Ph.D | Professor |

| 4 | Dr.R.Vinoth | Ph.D | Professor |

| 5 | Dr. N.Tamilselvan | Ph.D | Assistant Professor |

| 6 | Dr.K.Boopathy | Ph.D | Associate Professor |

| 7 | Mr.S.S.Jayaraman | M.E | Assistant Professor |

| 8 | Mr.D.Alagesan | M.E | Assistant Professor |

| 9 | Mr.V.Karthikeyan | M.E | Assistant Professor |

| 10 | Mr.P.Nithyanand | M.E | Assistant Professor |

| 11 | Mr.T.M Sakthi Muruga | M.E | Assistant Professor |

| 12 | Mr.Sambath Kumar | M.E | Assistant Professor |

| 13 | Mr.M.Nandhakumar | M.E | Assistant Professor |

| 14 | Mr. N.Selvakumar | M.E | Assistant Professor |

| 15 | Mr.R.Premraj | M.E | Assistant Professor |

| 16 | Dr.E.R. Sivakumar | Ph.D | Associate Professor |

| 17 | Dr. M Venkatesan | Ph.D | Associate Professor |

| 18 | Mrs.K.K.Megavarthini | M.E | Assistant Professor |

| 19 | Mr.V.Udhayakumar | M.E | Assistant Professor |

| 20 | Mr.M.Dineshkumar | M.E | Assistant Professor |

Opportunities for Quality Control Engineers in Industries

Date of the Event : 21.01.2023 (Saturday)

Time of the Event : 10.00 am to 11.30 am

Venue : Paavaiyammal hall

Event Organizers

1. Dr.A.KARTHIKEYAN AP/MECH /EEC

2. Mr.M.NANDHAKUMAR AP /MECH /EEC

Summary of the events:

Opportunities for Quality Control Engineers in Industries” is a online webinar conducted Final Year Mechanical Engineering students. This webinar was conducted by Mr.K.Jayaseelan, Quality Lead – Process ware Bangalore. This webinar provides a basic understanding and fundamental principles of Current Good Manufacturing Practices and also involves the documented training of good quality engineers in industries. This training program will examine how human factors/usability is the analysis of how people interact with design process. This webinar also provides the knowledge about manufacturing sector which persistently faces the urgency to adapt to the new innovative changes in technology to keep up with demand and stay competitive.

Number of Participants : Students: 85

Product Presentation On “Two Wheeler Vehicles”

Date of the Event : 21.01.2023 (Saturday)

Time of the Event : 11.30 am to 2.00 pm

Venue : Paavaiyammal hall

Event Organizers:

1. Dr.A.KARTHIKEYAN AP/MECH /EEC

2. Mr.M.NANDHAKUMAR AP /MECH /EEC

Summary of the events:

Product Presentation on Two Wheeler Vehicles.” is a Presentation contest conducted for Third Year Mechanical Engineering students. The main theme of this event is to make the students to think and present their design ideas in modeling their dream vehicle for the future. In this product presentation students can express their innovative ideas on two wheelers. Students can also present about various brands, automotive engines and different types of manufacturing technologies involved in production of Two Wheelers. At the End of the event students were provided with Online participation certificates after collecting their feedback about the event.

Number of Participants : Students: 85

Awareness Program on “Curriculum Development”

Date of the Event : 07.03.2023 (Tuesday)

Time of the Event : 10.00 am to 01.00 pm

Venue : Tiruvalluvar hall

Event Organizers:

1. Dr.N.Natrajan HoD /MECH /EEC

2. Mr.V.Karthikeyan AP /MECH /EEC

Summary of the events:

The event starts with welcoming of fellow faculty members continued with this Dr.N.Natarajan elaborated the details of awarding of degree in various consideration to the students and also introduced the latest announcements from both Anna university and AICTE to the faculty members regarding the Minor Degree program and its surplus opportunities to the student for getting the additional degree in the open theme, Dr.K.Bommanna raja, Principal Carried over the event for considering the additional credit points for awarding the Minor degree and the points from Both the directors were validated and appreciated by the fellow faculty members and the heads of the department

Number of Participants : Students: 32

Awards and Recognition

1. Life time achievement award – Dr.V.K.Shunmughanaathan at 21st ISTE TN section annual engineering faculty convention, Karpagam institute of technology, Coimbatore on 29th march 2019 by Indian society of technical education

2. Best Paper Award - R.Rajarajan on the paper titled An Intrinsic Power Prediction Technique to Enhance Power Quality Using Unified Power Quality Conditioner in Power System in International e-Conference on Green Technologies for Power generation, Communication and Health Care on 6th June,2020 organized by Department of ECE , EEE & BME at SPIHER, Chennai, India.

Participation

Student Participation

Date of the Event : 04.03.2023 (Saturday)

Time of the Event : 11.00 am to 11.30 am

Venue : Manufacturing Lab

Event Organizers

1. N.Venkatachalam ASP /MECH /EEC

2. V.Udayakumar AP /MECH /EEC

Summary of the events:

The event starts with welcoming of fellow faculty members continued with this Dr.N.Natarajan elaborated the details of awarding of Mr. Machinist to the students and also introduced the latest announcements regarding the Mr. Machinist program and its surplus opportunities to the student for getting the additional machining of component using Lathe in the open theme, Dr.K.Bommanna raja, Principal Carried over the event for considering the additional credit points for awarding the machining of component using Lathe and the points from both the directors were validated and appreciated by the fellow faculty members and the heads of the department.

Number of Participants : Students: 27

Date of the Event : 04.03.2023 (Saturday)

Time of the Event : 11.30 am to 11.45 am

Venue : Manufacturing Lab

Event Organizers:

1. N.Venkatachalam ASP /MECH /EEC

2. V.Udayakumar AP /MECH /EEC

Summary of the events:

The event starts with welcoming of fellow faculty members continued with this Dr.N.Natarajan elaborated the details of awarding of Mr. Machanic to the students and also introduced the latest announcements regarding the Mr. Machanic program and its surplus opportunities to the student for getting the additional machining of component using dismantling and assembly of engine in the open theme, Dr.K.Bommanna raja, Principal carried over the event for considering the additional credit points for awarding the dismantling and assembly of engine and the points from both the directors were validated and appreciated by the fellow faculty members and the heads of the department.

Number of Participants : Students: 25

Our Third Year Mechanical Engineering students Mr.Aditya Jaiswal & Mr.Mahesh Kumar have participated in “ZELOS 2023”

Our Third Year Mechanical Engineering students Mr.Aditya Jaiswal & Mr.Mahesh Kumar have participated in “ZELOS 2023” – National Level Technical Symposium held at “Kongu Engineering College, Perundurai”. They have secured the “Second Prize” in Paper Presention along with Cash Prize of Rs.1000. Mr.Mahesh Kumar also secured “FIRST PRIZE” in “Unite the Knots” Competition.

“VOLTRICK TK 23” – National Level Technical Symposium

Our Third Year Mechanical Engineering students Mr.Aditya Jaiswal & Mr.Mahesh Kumar have participated in “VOLTRICK TK 23” – National Level Technical Symposium held at “Kumarasamy Engineering College, Karur”. They have secured the “Second Prize” in Paper Presention along with Cash Prize of Rs.1000.

Placement

Alumni cum Industry Guest Lecture on “Career Prospects for Mechanical Engineers”

Date of the Event : 04.02.2023, Saturday

Time of the Event : 11.30 am to 01.00 pm

Venue : Smart class room, A4 Building, Department of Mechanical Engineering

Event Organizers

1. Dr.M. Venkatesan, AP/MECH /EEC

2. Mr.S. Sabeer Usan AP/MECH /EEC

Summary of the events:

Dr. N. Natarajan, Head and Professor, Department of Mechanical Engineering, Excel Engineering College gave welcome address, the participants of the lecture meeting and introduced the speaker.

Mr. Karthikeyan Chandrasekaran, Customer support analyst of Ultramain Software India PVT Ltd has started his lecture and the important points covered are:

The event kick started by the Resource Person talked about his memories and experiences in and about Excel Engineering College. The industrial world is in a constant state of change. The current and future prospects for the mechanical engineers were discussed with the students. The importance of knowing fundamentals and application of that principles in latest software were explained. The job opportunities in core and software fields are known by students after discussion. After completion of degree, higher studies and abroad studies with scholarship were encouraged.

A wide range of discussions including personal thoughts and doubts were discussed in the alumni cum industry lecture. From attending the event, the students got motivated and being ready to face the new job challenges.

Dr.N.Tamil Selvan, Associate Professor, Department of Mechanical Engineering, Excel Engineering College has given Vote of Thanks to the speaker and all the participants.

The student secretary Mr. Jahan, IInd year Mechanical Engineering presented the Memento to the guest as the token of gratitude.

The programme was successfully organized by Dr. M. Venkatesan, Associate Professor, Department of Mechanical Engineering.

Number of Participants : Professional: 05, Students: 50

Seminar on “How to prepare for Competitive/Higher study examinations”

Date of the Event : 04.03.2023 (Saturday)

Time of the Event : 11.00 am to 12.00 am

Venue : Tiruvalluvar hall

Event Organizers

1. Dr.N.Venkatachalam ASP /MECH /EEC

2. Mr.V.Udayakumar AP /MECH /EEC

Summary of the events:

The event starts with welcoming of fellow faculty members continued with this Dr.N.Natarajan elaborated the details of awarding of how to prepare for Competitive/Higher study examinations to the students and also introduced the latest announcements regarding the how to prepare for Competitive/Higher study examinations program and its surplus opportunities to the student for getting the additional How to prepare for Competitive/Higher study examinations in the open theme, Dr.K.Bommanna raja, Principal Carried over the event for considering the additional credit points for awarding the how to prepare for Competitive/Higher study examinations and the points from both the directors were validated and appreciated by the fellow faculty members and the heads of the department.

Number of Participants : Students: 41

Competitive Exam Coaching Awareness Program

| Title of the Activity: Competitive Exam Coaching Awareness Program | Date: 02.08.2023 |

| Name of Coordinator: | Dr.N.Venkatachalam ASP/Mech |

| Mapping with POs,PSOs: PO – 6,7,8,9,12, PSO- 2

| Number of Participants: 131 Students , 3 Staff Members

|

Description:

Department of Mechanical Engineering organized a Higher Studies Awareness Program on “Competitive Exam Coaching Awareness Program” to all the mechanical engineering stream students in our college ground on 02.08.2023 3.30 pm to 02.30 pm, during the session Thiru N. Jaya Prakash, Sales Executive-Academic Relations, ACE Engineering Academy, Chennai greeted the students for the Competitive Exam Coaching Awareness Program and responsibilities of each students to get higher studies in future. This program was coordinately organized by Dr. N. Venkatachalam, Associate Professor.