Industrial Visit

Industrial Visit

Rivera Coil Manufacturing India Pvt Ltd, Erode

Name of the company : Rivera Coil Manufacturing India Pvt Ltd, Erode

Date of visited : 01/08/2025

No of students visited : 49

No of faculties visited : 03

Company Profile:

RIVERA COIL MANUFACTURING INDIA PVT LTD is founded in 2022 by our Managing Director and CEO Mr. Nirmal Raj. Our Parent company RIVERA COIL REWINDING (founded in 2015) is one of the prime Rewinding & Servicing Company for LT/HT AC Motors, Alternators, DC Motors, Pumps, Hydro, Turbo & Wind Generators and Transformers. Rivera Coil Rewinding has handled electro mechanical jobs ranging from fractional kilowatts to 4X360MW, 11KV turbo generators.

Rivera Coil Manufacturing Plant is initiated for manufacture and supply of stator diamond coils and bars of rated voltage 415 V to 13800 V to worldwide along with winding kits for AC and DC Electrical Rotating Machines. Our Plant manufactures coils and bars for higher capacity also based on customer requirements. We are having in-house facility to manufacture coils as per OEM requirements and specifications.

We manufacture copper coils for pumps and motors and serve our customers in entire regions of Tamil Nadu, Karnataka, Kerala and Andhra Pradesh.

Objectives of the Visit

- 1. Understand the Product and Technology

- Experience Manufacturing Processes.

- Insight into Quality Control & Testing

- Learn Industry Applications & Use Cases

- Bridge Theory and Practice

- Understand Health, Safety & Operational Standards

- Enable Career and Professional Exposure

Key Areas of Expertise:

- Coil Winding & Manufacturing

- Quality Assurance & Testing

- Custom Design & Prototyping

- Tooling & Component Fabrication

- Energy Efficient Coil Solutions

- Transformer & Inductor Manufacturing

- Industrial & Automotive Applications

- Supply Chain & Logistics

Areas Covered During the Visit

- Company Overview

- Introduction to Rivera’s background and history.

- Overview of its role in the coil manufacturing industry.

- Understanding its market presence and clientele.

- Manufacturing Process

- Detailed walkthrough of the coil production line.

- Step-by-step explanation of raw material handling to finished product.

- Exposure to automated and semi-automated machinery used in production.

- Quality Control & Testing

- Insight into quality assurance protocols.

- Demonstration of testing equipment and procedures to ensure product standards.

- Overview of certifications and compliance measures.

- Research and Development (R&D)

- Overview of innovation and technology integration in coil design.

- Explanation of R&D activities for product improvement.

- Workplace Safety and Environmental Practices

- Safety measures followed on the shop floor.

- Environment-friendly initiatives and waste management techniques.

- Departments Visited

- Production Department

- Quality Assurance Department

- Research & Development Unit

- Inventory and Logistics Area

- Employee Interaction

- Interaction with engineers and plant supervisors.

- Understanding career opportunities and skillsets required.

Out Put of this Industrial Visit:

- Understanding of Coil Manufacturing Process

- Exposure to Industrial Machines & Equipment

- Quality Control and Testing

- Workplace and Safety Practices

- Industry Relevance and Applications

- Interaction with Experts

Conclusion:

The industrial visit to Rivera Coil Manufacturing India Pvt. Ltd. was a highly insightful and enriching experience. It provided a practical understanding of coil manufacturing processes, quality control measures, and industrial workflow management. Students gained firsthand exposure to modern machinery, safety protocols, and production techniques used in the electrical components industry.

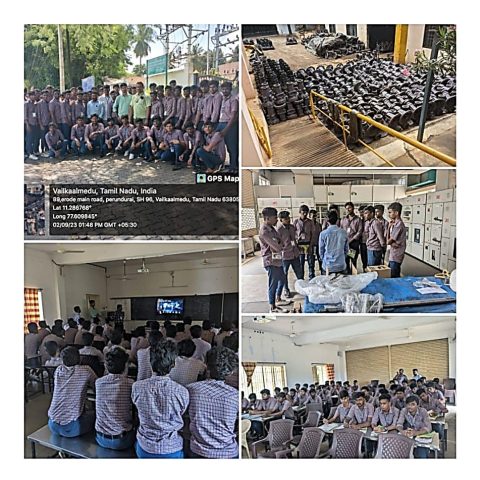

DMW CNC Solutions India private limited, Perundurai.

Name of the company : DMW CNC Solutions India private limited, Perundurai.

Date of visited : 19/07/2025

No of students visited : 48

No of faculties visited : 03

Company Profile:

DMW CNC Solutions India Private Limited is a company specializing in the manufacturing of high-precision machined components and sub-assemblies, with a focus on both ferrous and non-ferrous materials. They utilize advanced CNC machines and have a wide range of capabilities, including raw material sourcing and offering machining services. The company is ISO 9001, ISO 14001, OHSAS 18001, and IATF 16949 certified, highlighting their commitment to quality, environmental management, and safety.

Objectives of the Visit

- To understand the functioning and components of diesel engines

- To observe machining and repair processes

- To explore quality control methods used in engine servicing

- To gain insight into industrial safety and operational procedures

Key Areas of Expertise:

- Diesel engine rebuilding and servicing

- Cylinder head and crankshaft repair

- Precision machining and fabrication

- Component balancing and alignment

- Engine testing and calibration

Areas Covered During the Visit

- Engine Overhaul Section: We observed how diesel engines are disassembled, cleaned, inspected, and rebuilt. The staff explained the importance of each part and common failure points.

- Machining Workshop: This section housed lathes, milling machines, boring machines, and surface grinders. Demonstrations were given on how crankshafts, engine blocks, and cylinder heads are machined to precision.

- Testing Bay: Fully serviced engines were tested for performance, pressure, and emissions. The team used digital diagnostic tools and compression testers.

- Spare Parts and Storage Unit: The warehouse showcased an organized system for storing engine parts, fasteners, oils, and lubricants.

Key Learning’s

- Detailed understanding of diesel engine components and their working

- Importance of precision in machining and repair for engine performance

- Real-time observation of alignment, balancing, and tolerance checks

- Awareness of workplace safety measures like PPE, tool handling, and fire safety

- Introduction to basic troubleshooting and diagnostic tools used in the industry

Out Put of this Industrial Visit:

- Understanding of CNC Technology

· Industry Practices - Interaction with Experts

· Knowledge of Machine Tools and Software

· Awareness of Safety and Standards

· Career Orientation

Conclusion

The visit to DMW CNC Solutions India private limited, Perundurai was highly informative and enlightening. It helped bridge the gap between theoretical knowledge and practical applications. We thank DMW CNC Solutions India private limited, Perundurai for the hospitality and given the explanations of their production and safety. Also we submit out thanks to arrange the IV by our institution this enriching experience.

Agri Machinery Mela, Agriculture Department Salem.

Name of the company : Agri Machinery Mela, Agriculture Department Salem.

Date of visited : 30/08/2024

No of students visited : 88

No of faculties visited : 04

Company Profile:

As part of our academic and practical learning, we had the opportunity to visit the Agri Machinery Mela organized by the Tamil Nadu Agricultural Engineering Department at Salem. The Expo aimed to showcase the latest advancements in agricultural mechanization and promote the use of modern tools and technologies among farmers and students.

Objectives of the Visit

- To gain exposure to modern agricultural machinery and implements

- To understand the role of mechanization in sustainable farming

- To interact with industry experts and government officials

- To explore opportunities for innovation in agricultural engineering

Highlights of the Exhibition

The Agri Machinery Mela featured a wide range of exhibits and live demonstrations.

a. Tractor and Power Tiller Displays: Various models of tractors and power tillers from reputed manufacturers such as TAFE, Mahindra, and John Deere were displayed with technical specifications.

b. Soil Preparation Equipment: Implements such as rotavators, ploughs, harrows, and subsoilers were showcased, emphasizing their role in soil health and productivity.

c. Irrigation and Water Management Technologies: Drip irrigation systems, sprinklers, and solar-powered pumps were presented, highlighting water conservation techniques.

d. Post-Harvest and Processing Machinery: Machinery for threshing, milling, grading, and packaging of agricultural produce demonstrated the scope of value addition in farming.

e. Drone and Precision Farming Technology: Live demos of agricultural drones for spraying and surveying, as well as smart sensors for soil and crop monitoring, were conducted.

Interaction and Learning

- Expert Talks: Sessions were held by engineers, scientists, and officials from the Agricultural Engineering Department on the importance of mechanization.

- Farmer Feedback: We had interactions with local farmers who shared their practical experiences and challenges with modern machinery.

- Educational Value: The visit provided insights into emerging trends like AI in agriculture, automation, and climate-resilient tools.

Key Takeaways

- Mechanization is crucial for improving agricultural productivity and reducing labor dependency.

- Smart farming tools like GPS, IoT, and drones are transforming the agricultural landscape.

- There is a growing emphasis on sustainable and eco-friendly machinery.

Government support and subsidies are vital in making technology accessible to small and marginal farmers.

Conclusion

The visit to the Agri Machinery Mela was an enlightening experience. It bridged the gap between classroom learning and field-level applications. The expo helped us understand how engineering solutions can address real-world agricultural challenges. We thank Agriculture department for the hospitality and given the explanations of their production and safety .Also we submit out thanks to arrange the IV by our institution this enriching experience.

Linga Bhairavi Engineering Pvt Ltd, Coimbatore

Name of the company : Linga Bhairavi Engineering Pvt Ltd, Coimbatore.

Date of visited : 07/08/2024

No of students visited : 149

No of faculties visited : 05

Company Profile:

Linga Bhairavi Engineering Pvt. Ltd. Is a reputed engineering company based in Coimbatore, known for its expertise in precision machining, fabrication, and custom engineering solutions. The company primarily caters to sectors such as automotive, agriculture, textiles, and general engineering.

Key Areas of Operation:

- CNC Machining

- Metal Fabrication

- Custom Component Manufacturing

- Quality Control and Testing

- R&D Support

Objectives of the Visit:

- To gain exposure to real-time industrial operations.

- To understand the manufacturing processes and workflow.

- To observe the implementation of quality standards.

- To bridge the gap between theoretical learning and practical application.

Visit Highlights:

During the visit, we were guided by the company’s technical team, who explained various operations:

- Manufacturing Unit: We observed the working of CNC machines, lathe operations, and milling processes. The use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software in designing precision components was demonstrated.

- Quality Control Department: The team showed us how components are tested using instruments like Vernier calipers, micrometers, CMM (Coordinate Measuring Machines), and surface roughness testers to ensure dimensional accuracy and quality.

- Assembly and Finishing: The final stages of assembly and surface treatment (like painting and polishing) were explained. The company follows ISO standards for quality and safety.

Interaction with Professionals:

We had an interactive session with senior engineers who discussed:

- Industry expectations from engineering graduates.

- The importance of soft skills and continuous learning.

- Current trends in industrial automation and smart manufacturing.

Key Learning’s:

- Insight into real-time industrial processes.

- Understanding of how theoretical concepts are applied practically.

- Importance of teamwork and process discipline in manufacturing.

- Awareness of workplace safety and environmental considerations.

Conclusion

The industrial visit to Linga Bhairavi Engineering Pvt. Ltd. was a valuable learning experience. It enhanced our understanding of engineering practices and exposed us to the professional work environment. We thank Linga bhairavi for the hospitality and given the explanations of their production and safety .Also we submit out thanks to arrange the IV by our institution this enriching experience.

SAIL Refractory Company Ltd, Salem.

Name of the company : SAIL Refractory Company Ltd, Salem.

Date of visited : 04/04/2025 & 05/05/2024

No of students visited : 138

No of faculties visited : 06

Company Profile:

The Salem Steel Plant (SSP) is a unit of SAIL, This is under Maharatna PSU, Ministry of Steel, Government of India. It has established in the year of 1970s, It is producing high-quality stainless steel and special steel products

Key features of the plant include:

- Hot Rolling Mill (HRM)

- Cold Rolling Mill (CRM)

- Stainless Steel Melting Shop (SSMS)

- Steel Melting and Continuous Casting Facilities

SSP has received various quality certifications including ISO 9001, ISO 14001, and ISO 45001.

Objectives of the Visit:

- To understand the production process of stainless steel

- To learn about industrial safety and quality control measures

- To observe the integration of mechanical, electrical, and chemical engineering in steel production

- To gain insights into plant operations, logistics, and energy management

Visit Highlights:

a. Steel Melting Shop (SMS): We witnessed the process of melting raw materials using Electric Arc Furnaces (EAFs) and refining them to produce high-grade stainless steel.

b. Hot Rolling Mill (HRM): Observed how slabs are reheated and rolled into coils of desired thickness.

c. Cold Rolling Mill (CRM): Saw the process of cold reduction of coils for precise thickness and surface finish.

d. Quality Control Laboratory: Understood the various testing and inspection techniques used to ensure product quality.

Out Put of this Industrial Visit:

- Importance of safety measures and PPE in a high-temperature industrial environment

- Advanced automation and control systems used in steel manufacturing

- Environmental practices like effluent treatment and recycling

- Real-world application of engineering concepts like thermodynamics, metallurgy, and material science

Conclusion

The visit to SAIL – Salem Steel Plant was highly informative and enlightening. It helped bridge the gap between theoretical knowledge and practical applications. We thank SAIL-SSP for the hospitality and given the explanations of their production and safety .Also we submit out thanks to arrange the IV by our institution this enriching experience.

Indian Institute of Astrophysics, Kodaikananal

Name of the company : Indian Institute of Astrophysics, Kodaikananal

Date of visited : 17/02/2024

No of students visited : 140

No of faculties visited : 06

Company Profile:

The Kodaikanal Observatory, established in 1899, is one of the oldest and most prestigious solar observatories in India. It functions under the Indian Institute of Astrophysics (IIA), an autonomous research institute under the Department of Science and Technology, Government of India.

The observatory specializes in:

- Solar Physics Research

- Stellar Spectroscopy

- Historical Astronomical Data Archiving

- Optical and Infrared Instrumentation

Key instruments and facilities include:

- Solar Tunnel Telescope

- Spectroheliograph

- White Light Telescope

- Historical telescopes and photographic solar plates archive

Objectives of the Visit

- To understand the principles and methods of solar observation

- To learn about telescope mechanisms and data collection techniques

- To explore India’s contribution to space and astrophysical research

- To observe historical scientific instruments and records

Areas and Activities Covered

a. Solar Observation

We witnessed the working of solar telescopes, including how solar spectra and sunspots are observed using filters and optics.

b. Telescope Demonstration

The staff demonstrated how equatorially mounted telescopes track celestial bodies. We also learned about the solar tunnel telescope’s operation.

c. Spectroheliograph

An old but functional instrument used to photograph the Sun in various wavelengths was explained in detail, showing the evolution of solar imaging.

d. Photographic Plate Library

We were shown a century-old archive of solar images recorded on photographic plates, crucial for studying solar activity and sunspot cycles.

e. Museum and Historical Instruments

The observatory houses preserved historical telescopes and exhibits detailing India’s early astronomical efforts and global collaborations.

Key Learning’s

- The importance of long-term solar observations in understanding climate and space weather

- How light spectra reveal physical properties of celestial objects

- The precision required in telescope alignment and data recording

- The evolution of astronomical equipment from analog to digital technologies

- India’s significant contributions to global solar physics and astrophysics research

Diesel Machine Works, Perundurai, Erode

Name of the company : Diesel Machine Works, Perundurai, Erode.

Date of visited : 02/09/2023

No of students visited : 52

No of faculties visited : 02

Company Profile:

Diesel Machine Works is a reputed manufacturing and service-oriented firm specializing in diesel engine parts, reconditioning, and precision machining. The company caters to various sectors including agriculture, transport, power generation, and industrial engines.

Key Areas of Expertise:

- Diesel engine rebuilding and servicing

- Cylinder head and crankshaft repair

- Precision machining and fabrication

- Component balancing and alignment

- Engine testing and calibration

Objectives of the Visit

- To understand the functioning and components of diesel engines

- To observe machining and repair processes

- To explore quality control methods used in engine servicing

- To gain insight into industrial safety and operational procedures

Areas Covered During the Visit

a. Engine Overhaul Section: We observed how diesel engines are disassembled, cleaned, inspected, and rebuilt. The staff explained the importance of each part and common failure points.

b. Machining Workshop: This section housed lathes, milling machines, boring machines, and surface grinders. Demonstrations were given on how crankshafts, engine blocks, and cylinder heads are machined to precision.

c. Testing Bay: Fully serviced engines were tested for performance, pressure, and emissions. The team used digital diagnostic tools and compression testers.

d. Spare Parts and Storage Unit: The warehouse showcased an organized system for storing engine parts, fasteners, oils, and lubricants.

Key Learning’s

- Detailed understanding of diesel engine components and their working

- Importance of precision in machining and repair for engine performance

- Real-time observation of alignment, balancing, and tolerance checks

- Awareness of workplace safety measures like PPE, tool handling, and fire safety

- Introduction to basic troubleshooting and diagnostic tools used in the industry

Conclusion

The industrial visit to Diesel Machine Works, Perundurai, was a valuable learning experience. It provided practical exposure to diesel engine servicing and mechanical workshop practices, enhancing our understanding of real-world industrial applications. We thank DMW for the hospitality and given the explanations of their production and safety .Also we submit out thanks to arrange the IV by our institution this enriching experience.

Sea Blue Shipyard Limited, Cochin, Kerala

Name of the company : Sea Blue Shipyard Limited, Cochin, Kerala.

Date of visited : 21/03/2023

No of students visited : 80

No of faculties visited : 04

Company Profile:

Sea Blue Shipyard Ltd. is a leading private-sector shipbuilding and repair facility in South India, located on the banks of the Cochin backwaters. Established in 2003, the shipyard has developed expertise in constructing and repairing a wide variety of vessels including:

- Barges and Tugs

- Fishing Vessels and Patrol Boats

- Passenger Ferries

- Cargo and Inland Waterway Vessels

Facilities Include:

- Shipbuilding bays and dry docks

- Fabrication and welding workshops

- Assembly areas

- Outfitting and painting sections

- Quality control and inspection departments

Objectives of the Visit

- To understand ship construction and repair processes

- To observe the application of welding, fabrication, and propulsion systems

- To learn about dry-docking operations and hull maintenance

- To explore the integration of mechanical, electrical, and marine systems in shipbuilding

- To gain awareness about safety protocols in shipyard operations

Areas and Activities Covered

a. Fabrication and Assembly Bays

We observed the cutting and welding of steel plates to form ship hull sections using automated and manual welding processes.

b. Dry Docking Area

Engineers explained how ships are docked for repairs below the waterline, including propeller and rudder maintenance.

c. Engine Room Section

We learned about the installation and maintenance of marine engines, gearboxes, and auxiliary systems.

d. Painting and Outfitting Zone

Final surface coating, fitting of internal components, piping systems, and electrical layouts were demonstrated.

e. Design and Drafting Unit

The technical team shared how CAD and 3D modeling are used in designing hulls and ship structures, ensuring compliance with maritime standards.

Key Learnings

- Basics of ship design, modular construction, and floating principles

- Importance of precision welding, testing, and marine safety standards

- Coordination of multidisciplinary engineering in marine projects

- Dry-dock operations and underwater hull inspection techniques

- Challenges in shipbuilding including corrosion control and structural integrity

Conclusion

The visit to Sea Blue Shipyard, Cochin offered us real-world exposure to the complex and fascinating world of shipbuilding and repair. It strengthened our understanding of marine engineering principles and showed the critical role of technology and safety in maritime operations. We thank Sea blue shipyard for the hospitality and given the explanations of their production and safety .Also we submit out thanks to arrange the IV by our institution this enriching experience.

Anna Aluminium, Cochin, Kerala

Name of the company : Anna Aluminium, Cochin, Kerala.

Date of visited : 21/03/2023

No of students visited : 52

No of faculties visited : 02

Company Profile:

Anna Aluminum is a flagship unit of the Anna Group, known for its high-quality aluminum utensils, pressure cookers, and kitchenware. The company has built a strong brand presence in South India and continues to grow through product innovation and customer trust.

Key Products:

- Pressure cookers and cookware

- Aluminum utensils and containers

- Commercial and household kitchenware

- Customized industrial aluminum products

Manufacturing Capabilities Include:

- Aluminum casting and molding

- Die-making and pressing

- CNC machining and finishing

- Anodizing and polishing

- Quality control and packaging

Objectives of the Visit

- To understand the aluminum casting and manufacturing process

- To observe die-making and product design techniques

- To study quality control measures in mass production

- To understand branding, packaging, and marketing strategies

- To connect classroom theory with real-world industrial applications

Areas and Sections Visited

a. Casting and Foundry Section

We observed the process of melting aluminum, pouring it into molds, and forming basic utensil shapes. Safety protocols in high-temperature zones were explained.

b. Pressing and Forming Unit

This section involved mechanical and hydraulic presses used to shape products with precision. We learned how dies and molds are critical to achieving consistency.

c. Machining and Finishing

Machines like lathes, CNCs, and surface grinders are used to finish the product edges and surfaces. Anodizing and polishing enhance corrosion resistance and appearance.

d. Quality Control and Testing

Here, products undergo weight, thickness, and pressure resistance tests (especially for pressure cookers). Strict quality standards are followed before packaging.

e. Packaging and Branding Section

We saw how products are labeled, packed, and stored. Staff also explained their distribution network and how Anna Aluminum maintains its market presence.

Key Learnings

- Basics of aluminum casting and product design

- Role of mechanical presses and dies in shaping metal parts

- Importance of finishing processes like polishing and anodizing

- Industrial safety practices in metalworking environments

- Insights into supply chain and retail branding strategies

Conclusion

The industrial visit to Anna Aluminum, Cochin, was highly educational and provided valuable real-world exposure to the aluminum product manufacturing process. It offered us a clearer understanding of how theoretical knowledge in manufacturing, materials, and design is applied in a commercial production environment. We thank Anna Alumium for the hospitality and given the explanations of their production and safety .Also we submit out thanks to arrange the IV by our institution this enriching experience.

Salem Steel Plant, Salem

Name of the company : Salem Steel Plant, Salem

Date of visited : 23/03/2022

No of students visited : 50

No of faculties visited : 02

Company Profile:

The Salem Steel Plant, established in 1981, is one of India’s premier producers of high-quality stainless steel and special steel products. It operates under SAIL, a Maharatna company under the Government of India.

Major Facilities at SSP:

- Steel Melting Shop (SMS)

- Hot Rolling Mill (HRM)

- Cold Rolling Mill (CRM)

- Pickling and Annealing Line

- Quality Control and Testing Labs

SSP specializes in producing austenitic, ferritic, and martensitic stainless steel grades, which are used in automotive, construction, kitchenware, and defense industries.

Objectives of the Visit

- To understand the complete process of stainless steel manufacturing

- To observe the functioning of modern rolling mills and melting shops

- To learn about quality control and safety measures in a large plant

- To explore the real-time application of engineering principles in production

Departments and Sections Visited

a. Steel Melting Shop (SMS)

We observed the process of melting raw materials using Electric Arc Furnaces (EAF) and refining the molten steel using Argon Oxygen Decarburization (AOD).

b. Hot Rolling Mill (HRM)

Massive slabs are heated and passed through rollers to produce hot-rolled coils of desired thickness and width.

c. Cold Rolling Mill (CRM)

Hot-rolled coils are further processed to achieve better surface finish and closer dimensional tolerances. Annealing and pickling processes were demonstrated.

d. Quality Control Laboratory

Advanced instruments are used to test the mechanical, chemical, and metallurgical properties of finished products.

e. Environmental and Safety Division

We were briefed on safety practices, pollution control measures, and waste management systems implemented at SSP.

Key Learning’s

- Integration of automation, metallurgy, and mechanical systems in the steel production process

- Importance of safety and environmental protocols in a heavy industry

- Role of continuous casting, rolling, and finishing operations in maintaining product quality

- Real-time exposure to industrial machines like furnaces, roller mills, and testing equipment

- Insight into quality management and ISO certification processes in industrial plants

Conclusion

The visit to SAIL – Salem Steel Plant was highly informative and enlightening. It helped bridge the gap between theoretical knowledge and practical applications. We thank SAIL-SSP for the hospitality and given the explanations of their production and safety .Also we submit out thanks to arrange the IV by our institution this enriching experience.

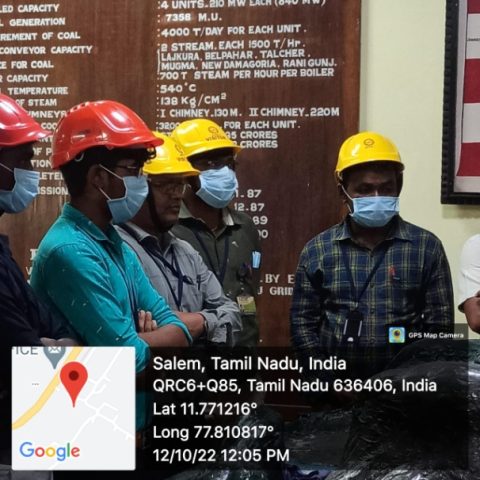

Mettur Thermal Power Station, Mettur, Salem

Name of the company : Mettur Thermal Power Station, Mettur, Salem

Date of visited : 12/10/20222

No of students visited : 82

No of faculties visited : 04

Company Profile:

The Mettur Thermal Power Station is one of the major coal-based power plants in Tamil Nadu. It is situated near the Stanley Reservoir in Mettur, Salem District.

Key Details:

- Operated by: TANGEDCO

- Installed Capacity: 1440 MW

- Units: 4 units of 210 MW and 1 unit of 600 MW

- Fuel Used: Coal (primary) and oil (auxiliary)

The plant plays a crucial role in supplying power to various regions across Tamil Nadu.

Objectives of the Visit

- To understand the generation and distribution of thermal power

- To learn about the function of boilers, turbines, generators, and cooling systems

- To gain insight into safety, pollution control, and maintenance protocols

- To observe the application of electrical and mechanical engineering principles in a large-scale power plant

Areas and Facilities Visited

a. Coal Handling Plant

We saw the system used to transport and crush coal before it is fed into the boilers.

b. Boiler and Furnace Section

This area explained how coal is burned to produce steam, with a focus on the combustion process and high-pressure steam generation.

c. Turbine and Generator Section

The steam produced is used to spin turbines connected to generators, converting mechanical energy into electrical energy.

d. Cooling Tower and Water Treatment Plant

We learned how water is used in the power cycle and how it is cooled and treated for reuse.

e. Control Room

The centralized control room monitors and manages all operations of the plant. Engineers explained SCADA systems and how load balancing is performed.

Key Learning’s

- Working principles of thermal power generation

- Integration of mechanical, electrical, and chemical systems in plant operations

- Environmental control measures like electrostatic precipitators and flue gas desulfurization

- Importance of regular maintenance and safety standards in heavy industries

- Role of instrumentation and control systems in power plant efficiency

Conclusion

The visit to Mettur Thermal Power Plant was a highly informative and technically enriching experience. It gave us a clear understanding of how electrical energy is generated from thermal sources and the engineering processes involved in power plant operation and management. We thank MTPS for the hospitality and given the explanations of their production and safety .Also we submit out thanks to arrange the IV by our institution this enriching experience.