Events Gallery

Events Gallery

2024-2025 EVENTS GALLERY

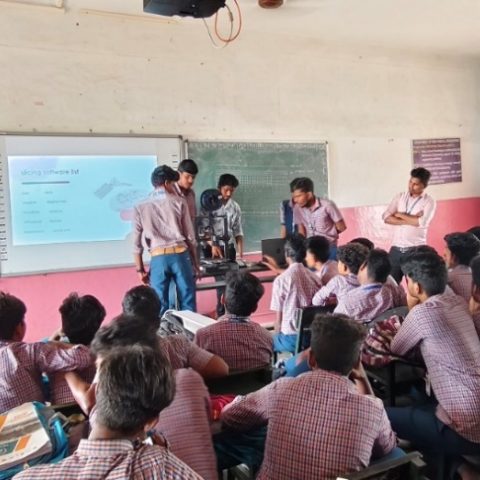

1.Emerging trends in CAD Technologies

Objective of the Program:

- To introduce students to the latest advancements in Computer-Aided Design (CAD) technologies.

- To expose students to real-world applications and future opportunities in design and manufacturing.

- To enhance students’ knowledge in smart modeling, 3D visualization, simulation, and integration with Industry 4.0 technologies.

Key Topics Covered:

- Evolution of CAD from 2D drafting to 3D parametric modeling

- Generative Design & Topology Optimization

- CAD in Additive Manufacturing (3D Printing)

- Role of AI & Automation in Design

- Cloud-Based CAD tools (Onshape, Fusion 360)

- Internet of Things (IoT) and CAD integration

- Real-time collaboration using cloud platforms

2. Leveraging of 5s & 6sigma in production, suppliation and optimization

Objective of the Program:

The main objective of this program was to introduce mechanical engineering students to the fundamentals and applications of 3D printing technology, design principles using CAD software, and real-world industrial use cases. The session aimed to bridge the gap between theoretical knowledge and practical applications in additive manufacturing.

Program Highlights:

- Introduction to Additive Manufacturing and 3D Printing Technology

- Overview of 3D Printing Materials and Techniques

- CAD Design Principles for 3D printing

- Hands-on demonstration of 3D modeling using [e.g., AutoCAD, SolidWorks, Fusion 360]

- Live demonstration of a 3D Printer in operation

- Case studies and industrial applications in automotive, aerospace, biomedical, and prototyping

4.Non-Destructive Testing

Objective of the Program:

The objective of this program was to introduce Diploma Mechanical Engineering students to Non-Destructive Testing (NDT) techniques, their industrial relevance, and applications in quality assurance, maintenance, and safety in manufacturing and production processes.

Program Highlights:

- Introduction to the concept of Non-Destructive Testing

- Types of NDT methods:

- Visual Inspection (VI)

- Liquid Penetrant Testing (LPT)

- Magnetic Particle Testing (MPT)

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Industrial applications and real-time case studies

- Demonstration of basic NDT equipment and testing procedures

- Importance of NDT in ensuring safety, reliability, and cost-effectiveness

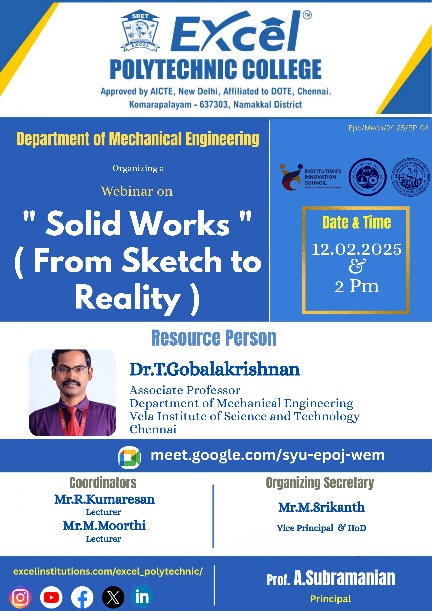

5.Solid Works ( From Sketch to Reality)

Objective of the Program:

The objective of this program was to introduce Diploma Mechanical Engineering students to Non-Destructive Testing (NDT) techniques, their industrial relevance, and applications in quality assurance, maintenance, and safety in manufacturing and production processes.

Program Highlights:

- Introduction to the concept of Non-Destructive Testing

- Types of NDT methods:

- Visual Inspection (VI)

- Liquid Penetrant Testing (LPT)

- Magnetic Particle Testing (MPT)

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Industrial applications and real-time case studies

- Demonstration of basic NDT equipment and testing procedures

- Importance of NDT in ensuring safety, reliability, and cost-effectiveness

6.Entrepreneurship and Startup

Objective of the Program:

The objective of this session was to create awareness about entrepreneurship and start-ups among diploma mechanical engineering students and to inspire them to consider self-employment and innovation-driven careers as viable alternatives to traditional job roles.

Program Highlights:

- Introduction to entrepreneurship and start-up ecosystem in India

- Identifying problems and converting them into business opportunities

- Basics of idea validation, market research, and product development

- Funding sources: government schemes (like PMEGP, MUDRA), private investors, incubators

- Case studies of successful mechanical engineering startups

- Skills required for an entrepreneur – innovation, leadership, risk-taking

- Government support for technical entrepreneurs (MSME, Startup India, etc.)

- Interactive session with real-life entrepreneurs

- Guidance on how to start a business after diploma

7.Opportunities and Challenges for Mechanical Engineers

Objective of the Program:

The primary objective of this session was to make students aware of the career opportunities, industry expectations, current challenges, and future trends in the field of Mechanical Engineering. It aimed to motivate diploma students to build relevant skills and stay updated with technological advancements.

Program Highlights:

- Design

- Job opportunities in government and private sectors

- Importance of skill development: CAD, CAM, CNC, NDT, Robotics, and Industry 4.0

- Higher education and certification options after diploma

- Challenges faced by mechanical engineers in the modern job market

- Adapting to emerging technologies and sustainability demands

- Resume building, internships, and soft skills development

8.Business Ideas and Startups

Objective of the Program:

- Inspire Entrepreneurial Thinking

- Provide Knowledge of Startup Fundamentals

- Develop and Refine Business Ideas

- Teach Business Model Development

- Explore Funding and Investment Opportunities

- Encourage Networking and Collaboration

- Present Real-World Case Studies

- Equip Participants with Practical Tools

- Foster a Startup Mindset

- Guide on Legal and Regulatory Basics

Program Highlights:

- Encourage participants to think creatively and identify potential business opportunities.

- Educate attendees on the basics of launching and managing a startup, including business planning, funding, marketing, and operations.

- Help participants brainstorm, evaluate, and validate their business ideas through structured exercises and feedback.

- Introduce tools such as the Business Model Canvas to help participants structure and test their business concepts.

- Inform participants about different funding options including bootstrapping, angel investors, venture capital, and government grants.

- Create opportunities for attendees to connect with potential co-founders, mentors, investors, and industry professionals.

- Share success stories and challenges from actual entrepreneurs to provide practical insights and motivation.

- Offer actionable resources, templates, and guidance to help participants move from idea to execution.

- Promote resilience, innovation, adaptability, and risk-taking as key traits for entrepreneurial success.

- Provide an overview of the legal aspects of starting a business such as registration, intellectual property, and compliance.

9.Sustainability Focused CAD tools

Objective of the Program:

- Enable Life Cycle Assessment (LCA)

- Optimize Material and Energy Use

- Encourage Reusability and Recyclability

- Integrate Real-Time Sustainability Feedback

- Support Regulatory Compliance and Standards

- Facilitate Collaboration Across Disciplines

Program Highlights:

- Allow engineers, environmental experts, and product designers to collaborate on sustainability goals within the same design environment.

- Help designers choose materials, processes, and configurations that reduce environmental impact from the early stages of design.

- Incorporate tools that analyse the environmental impact of a product from raw material extraction to disposal (cradle-to-grave approach).

- Support selection of sustainable materials and energy-efficient designs to minimize waste and reduce carbon footprint.

- Assist in designing components and products that are easy to disassemble, recycle, or reuse.

- Provide instant feedback or metrics (e.g., embodied carbon, energy consumption) to guide sustainable decision-making during the design phase.

- Align designs with environmental standards and certifications like LEED, RoHS, ISO 14001, etc.

2023 -2024 EVENTS GALLERY

1. MSME, Startup & Financial Aspects

Objective of the Program:

- To introduce the concept of MSMEs and their role in India’s economy.

- To encourage students to consider entrepreneurship as a career option.

- To explain the startup process, including idea validation, business model creation, and registration.

- To highlight financial aspects, such as funding sources, government schemes, budgeting, and cash flow management.

Outcomes of the Program

- Students gained clear knowledge of how to start and register MSMEs.

- Awareness about Startup India, financial planning, and government support.

- Boosted confidence among students to explore entrepreneurship in core sectors like fabrication, repair services, component manufacturing, etc.

- Students were introduced to real-life case studies of diploma holders who became successful entrepreneurs.

2.Lean Manufacturing

Objective of the Program:

- The fundamental principles of Lean Manufacturing.

- Tools and techniques used in lean production.

- Waste reduction strategies in manufacturing systems.

- The importance of continuous improvement (Kaizen) and value stream mapping.

Topics Covered:

- Introduction to Lean Manufacturing

- The Five Lean Principles

1. Value

2. Value Stream

3. Flow

4. Pull

5. Perfection - Types of Waste (Muda) in Manufacturing

Overproduction, Waiting, Transport, Over-processing, Inventory, Motion, Defects

- Lean Tools and Techniques:

5S System, Kaizen (Continuous Improvement), Value Stream Mapping, Just-in-Time (JIT), Kanban System, Poka-Yoke (Error Proofing)

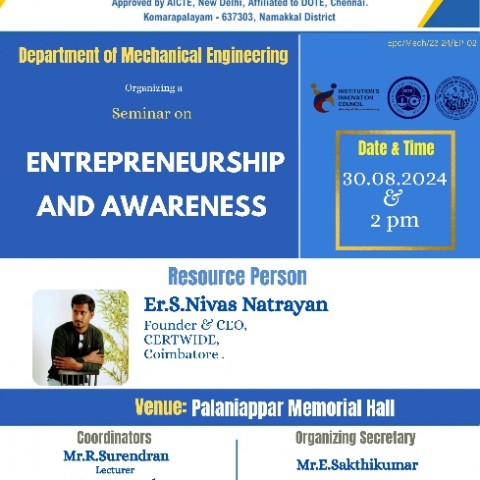

3.Entrepreneurship and Awareness

Objectives of the Program

- To create awareness about entrepreneurship as a career option.

- To educate students about the process of starting and managing a business.

- To highlight opportunities for mechanical engineers in MSMEs and start-ups.

- To introduce government schemes and funding opportunities for start-ups.

Key Highlights

- Interactive sessions with successful entrepreneurs.

- Real-world examples from the mechanical industry.

- Hands-on group activities on ideation and BMC (Business Model Canvas).

- Students expressed interest in starting small-scale businesses.

- Enhanced understanding of entrepreneurial support systems in India.

- Encouragement for project-based learning and innovation

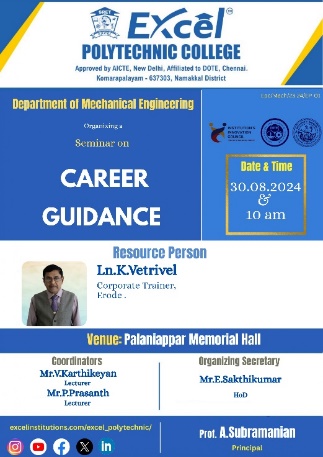

4. Career Guidance

Objectives

- To guide students on career opportunities after diploma.

- To inform students about higher education and lateral entry options.

- To raise awareness about job roles in the mechanical and manufacturing sectors.

- To motivate students to pursue their career goals confidently.

Key Highlights

- Detailed guidance on job roles in public and private sectors.

- Information on lateral entry to B.E./B.Tech programs.

- Industry-oriented resume and interview preparation tips.

- Motivational talk by successful alumni.

- Students gained clarity on post-diploma options.

- Increased interest in lateral entry engineering courses.

- Better awareness of industry expectations.

- Positive feedback regarding the real-life experiences shared.

5. How to prepare for competitive exams and expectation of industry

Objectives of the Program

- To educate students on how to prepare for competitive exams such as:

- Government Jobs: SSC JE, RRB JE, DRDO, ISRO, State PSCs.

- Higher Studies: Lateral entry to B.E./B.Tech through entrance exams.

- Private Sector Tests: Campus placement exams.

- To help students understand what the mechanical industry expects from diploma graduates.

Highlights of the Program Session

- Guest lecture by an industry professional/college faculty.

- Interaction with alumni placed in core companies.

- Tips shared for resume building and interview preparation.

- Sample mock test session conducted.

- Systematic preparation, dedication, and time management are key to clearing competitive exams.

- Industries seek skilled, job-ready candidates with both technical and soft skills.

Students must upgrade their knowledge through internships, online certifications, and real-world practice

6. Product Design and Manufacturing

Objectives of the Program

- To introduce students to the process of product design, from concept to production.

- To familiarize students with modern manufacturing techniques and tools.

- To explain the importance of design thinking, prototyping, and CAD/CAM tools.

- To align students’ knowledge with current industry standards and expectations in manufacturing.

Highlights of the Program Session

- Live demonstration of 3D modeling using SolidWorks

- Prototype design activity for a basic product (e.g., a bottle cap, gear assembly)

- Display of manufactured components using CNC machine/3D printer

- Students understood the entire product lifecycle from concept to production.

- Gained exposure to industrial practices in design and manufacturing.

- Developed an interest in pursuing certifications in CAD/CAM

- Improved readiness for internships, placements, and technical projects.

7. Non Destructive Testing and QC

Objectives of the Program

- The primary aim of this program was to familiarize diploma students with:

- Fundamental concepts of Non-Destructive Testing techniques.

- The importance of quality control in manufacturing.

- Real-world applications and practical demonstrations of NDT methods.

- Industry standards and safety practices in inspection processes.

Topics Covered:

- Introduction to Non-Destructive Testing

- Principles and Methods of NDT

- Visual Inspection (VI)

- Dye Penetrant Testing (DPT)

- Magnetic Particle Testing (MPT)

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Applications in mechanical and manufacturing industries

- Basics of Quality Control and Assurance

- Quality standards (ISO, ASME, ASTM)

- Role of NDT in defect detection and product reliability

- Hands-on demonstration of DPT and MPT

2022 -2023 EVENTS GALLERY

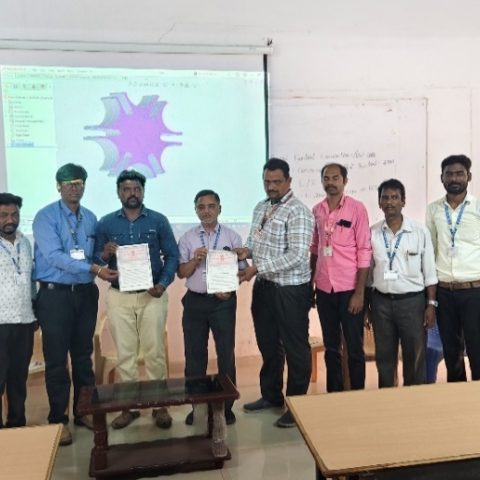

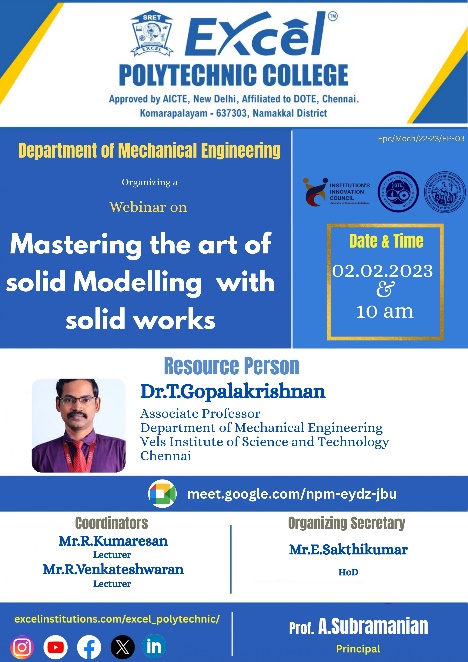

1.Mastering the art of Solid Modelling with Solid works

Objective of the Program:

- To introduce students to the SolidWorks interface and tools.

- To help students develop skills in 3D part modeling, assembly design, and drafting.

- To demonstrate the application of CAD in real-world mechanical engineering projects.

- To prepare students for industry demands and boost their employability.

Outcomes of the Program

- Students became familiar with professional CAD modeling

- Live modeling session: Creating a spur gear, valve body, or piston in SolidWorks.

- Practice exercises were given to students for individual modeling.

- Tips for clearing Solid Works Associate Certification (CSWA) were shared.

- Improved skills in designing mechanical parts and assemblies.

- Awareness of career opportunities in CAD design, drafting, and product development.

- Encouraged students to pursue certifications and internships related to design engineering.

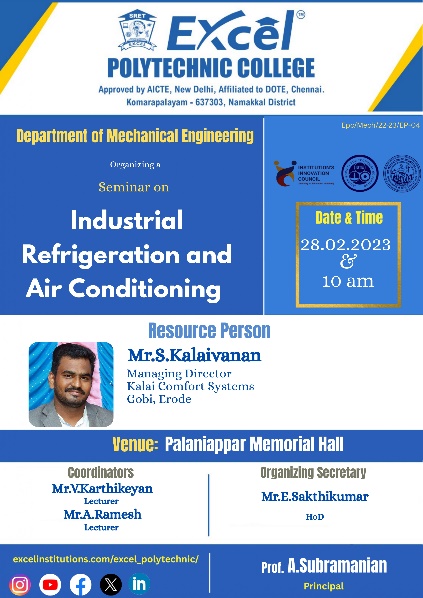

2. Industrial Refrigeration and Air Conditioning

Objective of the Program:

- To explain the fundamentals of refrigeration and air conditioning systems.

- To familiarize students with industrial-scale applications in HVAC (Heating, Ventilation, and Air Conditioning).

- To introduce the working of components like compressors, condensers, evaporators, and expansion devices.

- To discuss energy efficiency, environmental concerns (refrigerants), and system maintenance.

Outcomes of the Program

- Improved understanding of cooling system design and function.

- Awareness of the HVAC industry’s scope, job roles, and required skills.

- Students gained clarity on environmental aspects and new technologies in refrigeration.

- Encouraged students to take up internships/certifications in HVAC fields (e.g., ASHRAE, RAC, Skill India programs).

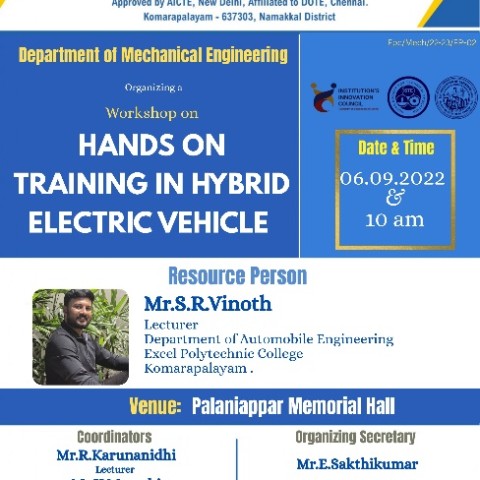

3.Hands on Training in Hybrid Electric Vehicles

Objective of the Program:

- To introduce students to the principles of hybrid vehicle technology.

- To explain the architecture, components, and energy flow in HEVs.

- To provide hands-on exposure to hybrid powertrains and diagnostic tools.

- To build awareness of career opportunities in the EV and HEV sectors.

Outcomes of the Program

- Students gained a practical understanding of how HEVs operate.

- Increased awareness of hybrid technologies and their future in transportation.

- Enhanced interest in pursuing automotive and EV-specific careers or higher studies.

- Developed foundational knowledge to prepare for EV/HEV technician certifications.

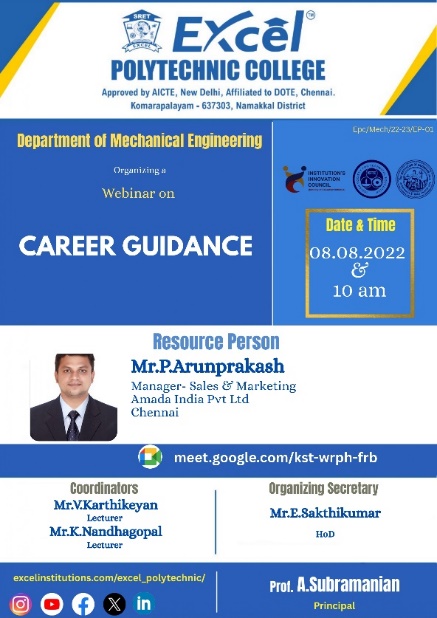

4.Career Guidance

Objectives

- To guide students on career opportunities after diploma.

- To inform students about higher education and lateral entry options.

- To raise awareness about job roles in the mechanical and manufacturing sectors.

- To motivate students to pursue their career goals confidently.

Key Highlights

- Detailed guidance on job roles in public and private sectors.

- Information on lateral entry to B.E./B.Tech programs.

- Industry-oriented resume and interview preparation tips.

- Motivational talk by successful alumni.

- Students gained clarity on post-diploma options.

- Increased interest in lateral entry engineering courses.

- Better awareness of industry expectations.

- Positive feedback regarding the real-life experiences shared.